Understanding Regulating Wheel Speed in Centerless Grinding Operations

Key Takeaways

- Regulating wheel speed directly controls workpiece rotation, creating a precise 1:1 material removal ratio that makes centerless grinding twice as accurate as traditional methods

- Speed synchronization is critical—adjusting grinding wheel speed requires corresponding changes to feed rate and regulating wheel speed to maintain balance

- Start with baseline parameters: 20-40 RPM for regulating wheel, +1 to +3 degree angle of inclination, and monitor for warning signs like excessive vibration or inconsistent surface finish

- Improper speed relationships cause failures that cost manufacturers $50,000 per hour in downtime, but proper speed control catches problems weeks before catastrophic failure

Your regulating wheel speed isn’t just another dial to adjust.

It’s the control point that determines whether your parts meet spec or end up as scrap. The relationship between your grinding wheel and regulating wheel creates the precision that makes centerless grinding twice as accurate as traditional OD or ID grinding.

When you get the speed balance right, your process hums along smoothly. When you don’t, you’re looking at chatter marks, grinding burns, and expensive downtime.

Here’s what you need to know about regulating wheel speed to keep your operations running at peak performance.

Understanding the Critical Speed Relationship

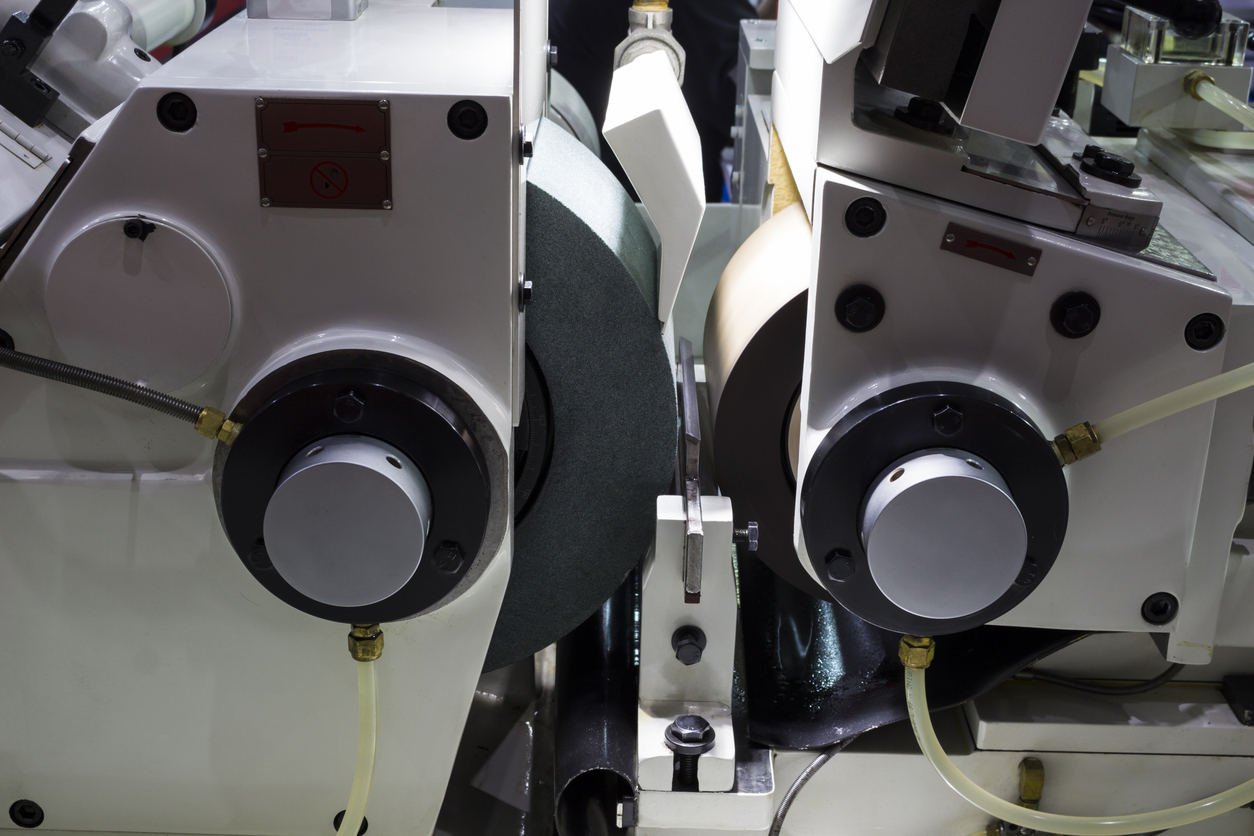

Your grinding wheel operates at approximately 35 meters per second—that’s roughly 4,000 to 6,500 surface feet per minute. Meanwhile, your regulating wheel runs at a much slower 10-50 meters per minute.

This speed differential creates controlled material removal.

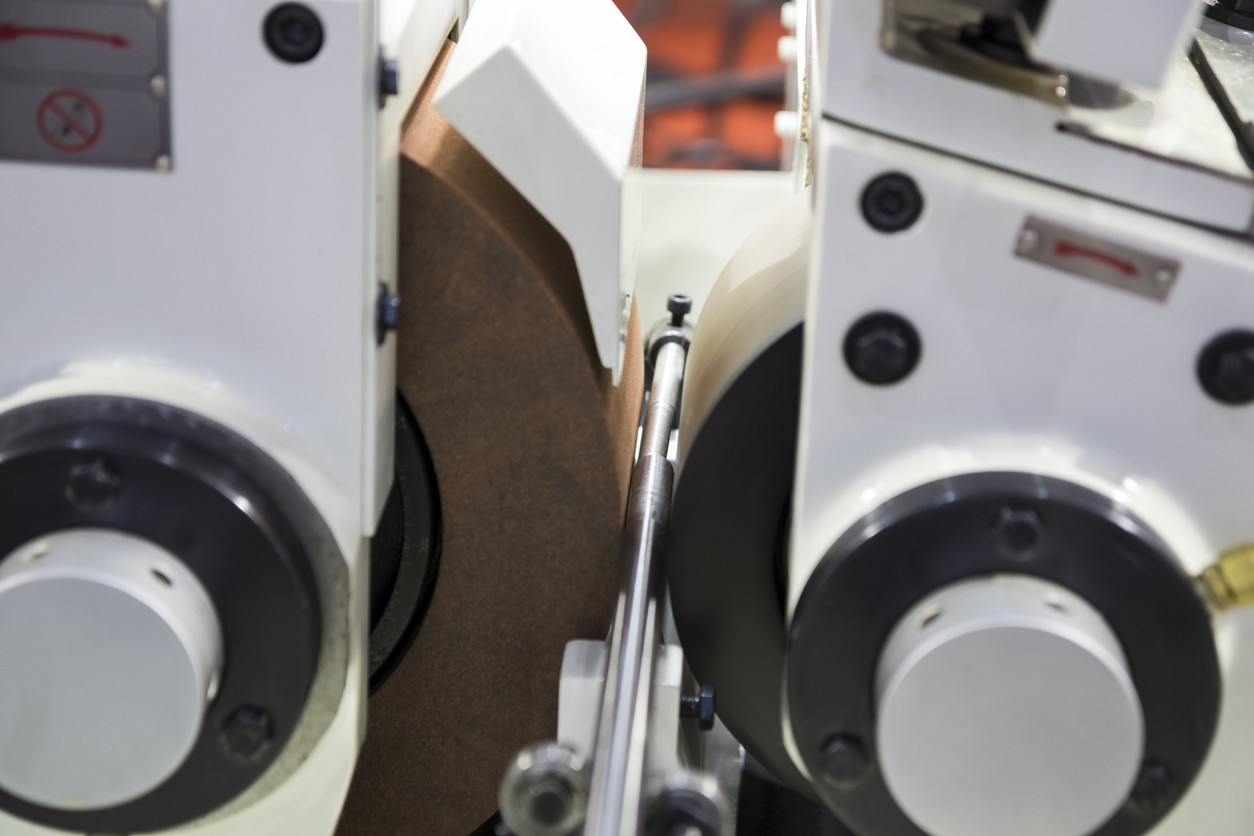

The regulating wheel directly determines your workpiece rotation speed. Your part’s linear speed matches the regulating wheel speed almost exactly. This relationship is what gives centerless grinding its remarkable precision—for every 0.001 inch the wheel moves in, exactly 0.001 inch comes off the workpiece diameter.

The speed ratio between these wheels matters more than you might think.

The grinding speed ratio (qs) represents the relationship between grinding wheel speed and workpiece speed. Industry standards recommend keeping this ratio between 60 and 120.

Push the ratio too high, and you risk grinding burns that ruin surface finish and dimensional accuracy. Drop it too low, and chatter marks appear, creating quality issues that slow production.

Speed Synchronization Prevents Costly Problems

Your grinding and regulating wheels need to work in harmony.

When you modify grinding wheel speed, you need to adjust feed rate and regulating wheel speed accordingly. Skip this step, and the wheels lose balance. The consequences show up fast—dimensional defects, surface irregularities, and safety issues that put both personnel and equipment at risk.

Unexpected centerless grinder breakdowns cost manufacturers an average of $50,000 per hour in lost production. Many of these failures stem from improper speed relationships between wheels.

The good news? Component failures show warning signs weeks before catastrophic failure. Proper speed regulation helps you catch these issues early, preventing costly emergency repairs that typically run 3-5 times more than planned maintenance.

Optimizing Speed for Material Removal and Surface Finish

The speed difference between your wheels controls how fast you remove material.

In the in-feed method, the regulating wheel spins the part at one speed while pushing it toward the grinding wheel, which spins faster. The greater the speed difference, the faster your removal rate.

This relationship gives you control over throughput without sacrificing quality.

For throughfeed operations, your regulating wheel angle of inclination typically ranges from +1 to +3 degrees. This angle, combined with regulating wheel RPMs, determines your part throughfeed rate in inches per minute. The recommended starting rotational speed for the control wheel sits at 20-40 revolutions per minute.

Surface finish responds directly to speed adjustments. Centerless grinding achieves tolerances of less than 0.0001 inch.

Best Practices for Regulating Wheel Speed Control

Start with recommended baseline parameters

Begin with a speed ratio between 60 and 120. Set your regulating wheel at 20-40 RPM for most applications. Adjust the angle of inclination between +1 and +3 degrees based on your material and part requirements.

Monitor the relationship between all parameters

Your grinding wheel speed, regulating wheel speed, and feed rate work together. Change one, and you need to evaluate the others. Keep detailed records of what works for different materials and part specifications.

Watch for warning signs

Excessive vibration, unusual noise, or inconsistent surface finish all point to speed imbalance. Address these issues immediately before they escalate into equipment damage or part rejection.

Implement preventive maintenance

Regular inspection and adjustment of speed controls prevents the majority of problems. Check wheel condition, spindle bearings, and drive systems on a consistent schedule.

Test and validate changes

When you adjust speeds, run test parts and measure results. Small incremental changes help you find the optimal balance without risking large batches of parts.

Partner With Experts

Getting regulating wheel speed right requires both technical knowledge and practical experience.

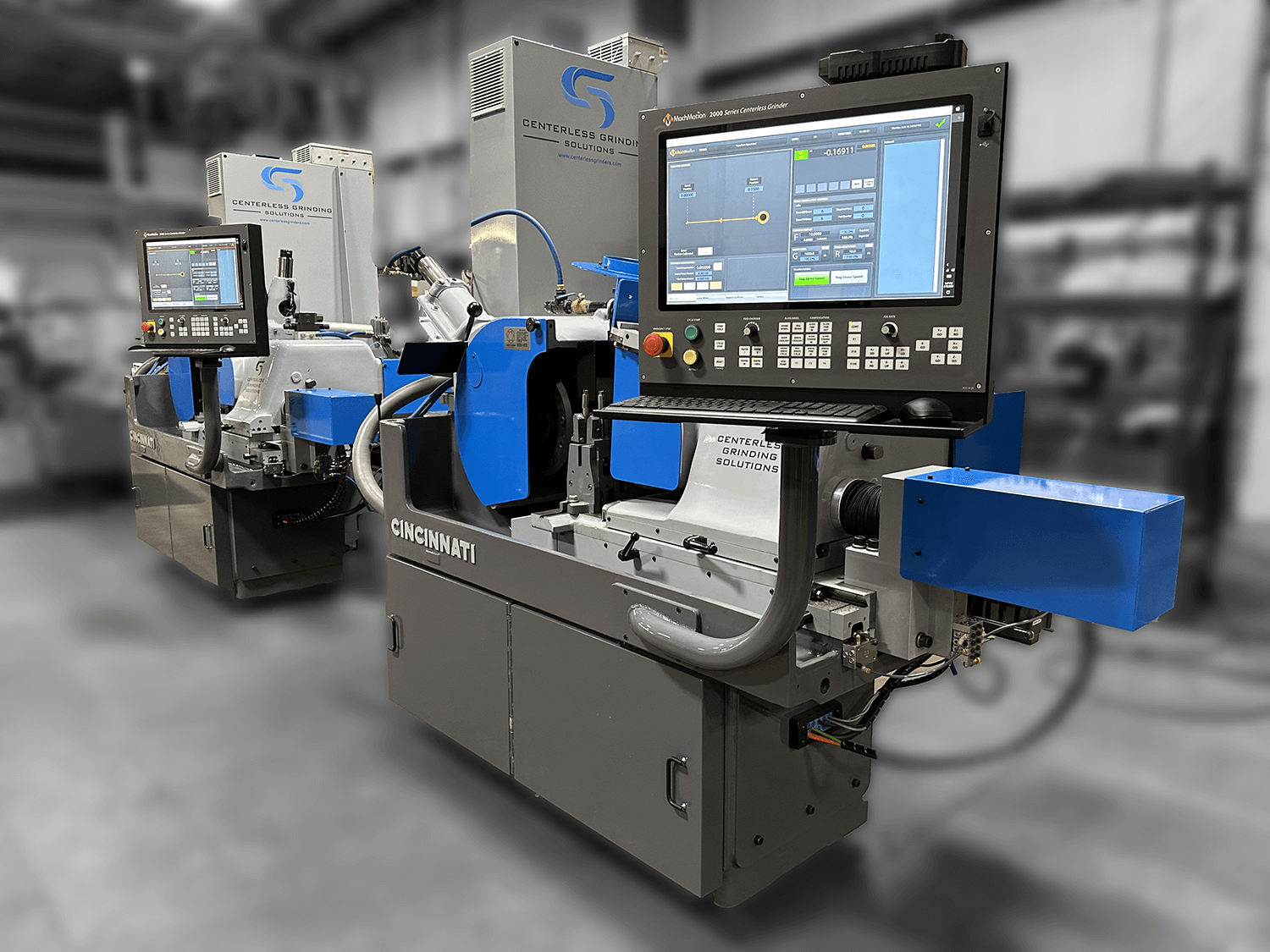

At Centerless Grinding Solutions, we’ve spent over 30 years helping maintenance managers, plant managers, and owners optimize their centerless grinding operations. We understand the speed relationships that drive precision and the adjustments that prevent costly downtime.

Whether you need machine remanufacturing, parts replacement, or expert guidance on optimizing your process parameters, we’re here to help. Our team takes the time to understand your specific challenges and delivers solutions that keep your operations running smoothly.

Ready to optimize your centerless grinding performance? Contact our team at Centerless Grinding Solutions. We’ll work with you to ensure your regulating wheel speed and all related parameters are dialed in for maximum efficiency and precision.

Let’s keep your machines running at peak performance.