Troubleshooting Component Issues: Signs Your Centerless Grinder Parts Need Attention

Unexpected centerless grinder breakdowns cost manufacturers an average of $50,000 per hour in lost production, yet 80% of component failures show warning signs weeks before catastrophic failure occurs. Recognizing early signs your centerless grinder parts need attention prevents costly emergency repairs while maintaining consistent production quality. Smart manufacturers use systematic troubleshooting approaches to identify component issues before they disrupt operations.

Component degradation happens gradually, making early detection challenging without proper knowledge of failure indicators. Understanding specific symptoms associated with worn spindles, deteriorating bearings, and failing hydraulic systems enables proactive maintenance that extends equipment life while minimizing unplanned downtime.

Understanding Centerless Grinder Component Failure Patterns

What causes centerless grinder component failures? Component failures typically result from normal wear, inadequate lubrication, contamination, misalignment, or exceeding design specifications during operation.

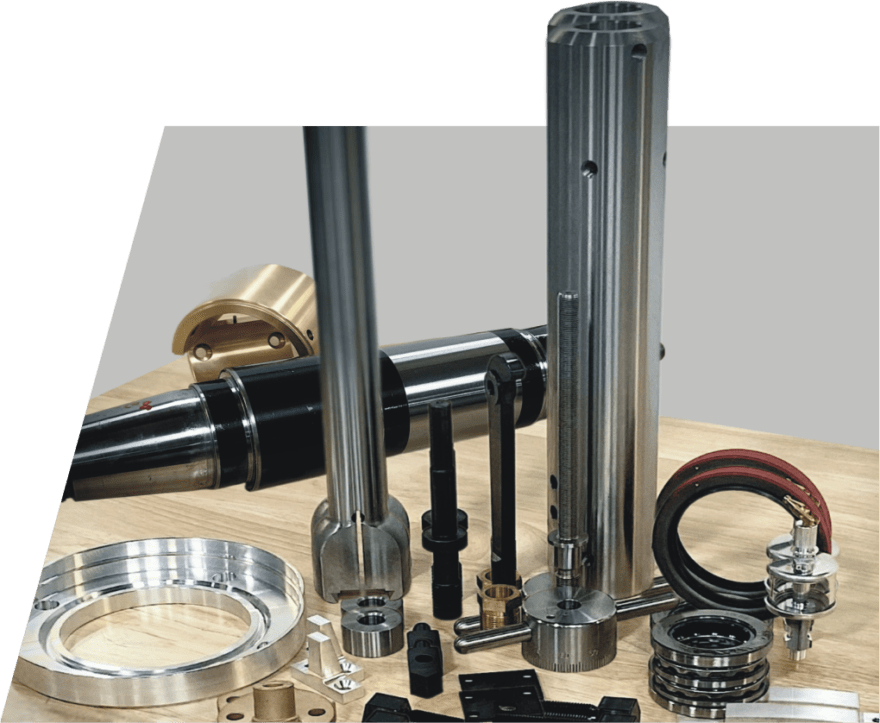

Critical components in centerless grinding systems include spindle assemblies, bearing systems, hydraulic components, drive mechanisms, and electrical controls. Each component exhibits specific failure patterns that manifest through distinct symptoms when deterioration begins.

Early detection of component issues prevents minor problems from escalating into major failures requiring extensive repairs or complete rebuilds. Systematic monitoring and documentation help establish baseline performance levels for comparison during routine inspections.

10 Critical Warning Signs Your Centerless Grinder Needs Component Attention

Recognizing these warning signs early prevents catastrophic failures and costly production disruptions:

- Unusual vibration patterns during grinding operations

- Temperature increases in spindle or bearing housings

- Oil contamination or unusual fluid discoloration

- Grinding quality degradation despite proper setup

- Unusual noise levels from rotating components

- Hydraulic pressure fluctuations during operation

- Increased power consumption without load changes

- Dimensional accuracy drift across production runs

- Surface finish deterioration on finished parts

- Control system error messages or erratic behavior

Spindle Assembly Issues: Early Detection and Prevention

Identifying Spindle Bearing Problems

Spindle bearings represent the most critical components in centerless grinding operations, with failure often resulting in complete machine shutdown. Spindle bearing problems typically manifest through increased vibration, temperature rise, and unusual noise during operation.

High-frequency vibration indicates bearing race damage or contamination, while low-frequency vibration suggests alignment issues or unbalance conditions. Temperature monitoring reveals bearing stress before audible symptoms appear, enabling proactive replacement scheduling.

Oil analysis provides early warning of bearing deterioration through detection of metallic particles and contamination levels. Regular oil sampling creates trending data that predicts bearing replacement timing before performance degradation affects grinding quality.

Spindle Runout and Alignment Issues

Excessive spindle runout creates grinding quality problems including poor surface finish, dimensional variations, and accelerated wheel wear. Runout measurements exceeding 0.0001″ TIR indicate spindle problems requiring immediate attention to prevent further deterioration.

Thermal growth patterns affect spindle alignment as temperatures fluctuate during production cycles. Understanding normal thermal behavior helps distinguish between temporary thermal effects and permanent alignment problems requiring correction.

Dynamic balancing becomes critical as spindle speeds increase, with unbalance forces causing premature bearing failure and grinding quality problems. Professional balancing services restore optimal performance while extending component life.

Hydraulic System Component Troubleshooting

Pump Performance Degradation

Hydraulic pump deterioration typically manifests through pressure loss, flow reduction, and increased noise levels during operation. Pump efficiency decreases gradually, making performance monitoring essential for early problem detection before complete failure occurs.

Contamination represents the leading cause of hydraulic pump failure, with particles causing internal component wear and seal damage. Regular fluid analysis and filtration system maintenance prevent contamination-related failures while extending pump service life.

Cavitation damage occurs when pump suction conditions create vapor bubbles that collapse violently, causing erosion and performance loss. Proper suction line design and maintenance prevent cavitation while ensuring optimal pump performance.

Valve and Actuator Problems

Hydraulic valves experience wear through normal operation, with internal leakage and response time degradation indicating replacement necessity. Valve problems affect grinding cycle timing and force control, directly impacting part quality and production efficiency.

Seal deterioration in hydraulic actuators causes external leakage and reduced force output, affecting grinding parameters and safety systems. Regular seal replacement prevents environmental contamination while maintaining system performance.

Accumulator performance degrades over time as gas charges leak and bladders deteriorate. Proper accumulator maintenance ensures consistent hydraulic response and protects system components from pressure spikes.

Electrical Control System Component Issues

Drive System Problems

Variable frequency drives (VFDs) control spindle and regulating wheel speeds with precision required for optimal grinding performance. Drive system problems typically manifest through speed instability, fault codes, and irregular motor operation affecting grinding consistency.

Power quality issues including voltage fluctuations and harmonic distortion accelerate drive component aging while causing erratic performance. Proper power conditioning protects sensitive electronics while ensuring stable operation.

Motor insulation degradation occurs gradually through thermal cycling and contamination exposure. Regular insulation testing predicts motor replacement timing before unexpected failures disrupt production.

Control Panel and Sensor Failures

Temperature sensors, pressure transducers, and position feedback devices provide critical information for automated grinding systems. Sensor failures often cause erratic machine behavior and false alarms that confuse operators and affect productivity.

Control panel components including contactors, relays, and circuit breakers experience wear through normal switching operations. Preventive replacement based on cycle counts prevents unexpected control system failures.

Wiring harnesses and connections deteriorate through vibration, temperature cycling, and contamination exposure. Regular inspection and maintenance prevent intermittent electrical problems that are difficult to diagnose.

Frequently Asked Questions About Centerless Grinder Component Issues

How often should centerless grinder components be inspected? Inspect critical components weekly during operation, with monthly comprehensive inspections including vibration analysis, temperature monitoring, and fluid sampling for trending analysis. This helps with troubleshooting centerless grinder problems.

What are the most common signs of bearing failure? Increased vibration, temperature rise, unusual noise, and oil contamination indicate bearing problems. Temperature increases of 20°F above normal suggest immediate attention is needed.

When should hydraulic fluid be replaced? Replace hydraulic fluid when contamination levels exceed ISO 18/16/13 cleanliness standards or when fluid analysis shows degradation. Typically every 2,000-4,000 operating hours depending on conditions.

How do I know if my spindle needs rebuilding? Runout exceeding 0.0001″ TIR, temperature increases above 160°F, vibration levels above 0.1 IPS, or visible oil contamination indicate spindle rebuilding necessity.

What causes frequent grinding wheel loading? Inadequate coolant flow, wrong wheel specification, excessive grinding forces, or spindle problems can cause wheel loading. Check coolant system and grinding parameters first.

Why does my grinder produce inconsistent surface finish? Spindle wear, vibration issues, contaminated coolant, worn work rest blades, or improper wheel dressing typically cause surface finish problems.

Component Monitoring and Predictive Maintenance Strategies

Vibration Analysis for Component Health

Vibration monitoring provides early warning of rotating component problems before audible symptoms develop. Baseline vibration measurements establish normal operating conditions for comparison during routine monitoring, enabling detection of gradual deterioration.

Frequency analysis identifies specific component problems through characteristic vibration signatures associated with bearing defects, unbalance conditions, and alignment issues. Professional vibration analysis services provide detailed diagnostics and trending data.

Portable vibration meters enable regular monitoring of critical components without specialized training, while permanent monitoring systems provide continuous data collection for automated alarming and trending.

Temperature Monitoring Systems

Thermal monitoring reveals component stress before mechanical symptoms appear, enabling proactive maintenance scheduling. Infrared thermography identifies hot spots and thermal patterns indicating lubrication problems, alignment issues, or excessive loading.

Permanent temperature sensors on critical components provide continuous monitoring with alarm capabilities for immediate notification of temperature excursions. Data logging enables trending analysis for predictive maintenance planning.

Thermal imaging surveys during operation reveal problems invisible to visual inspection, including electrical connection issues, bearing problems, and hydraulic system inefficiencies.

Oil Analysis Programs

Systematic oil analysis provides detailed information about component condition and contamination levels affecting system performance. Trending analysis reveals gradual component wear enabling planned maintenance before failures occur.

Particle counting indicates contamination levels affecting component life, while spectroscopic analysis identifies specific wear metals indicating particular component problems. Water content and acidity levels reveal fluid degradation requiring attention.

Regular sampling intervals create trending data that predicts component replacement timing while optimizing fluid change intervals based on actual condition rather than arbitrary schedules.

Diagnostic Tools and Measurement Techniques

Essential Diagnostic Equipment

Professional diagnostic equipment enables accurate assessment of component condition and performance parameters. Basic diagnostic tools include vibration meters, temperature guns, and pressure gauges for routine monitoring by maintenance personnel.

Advanced diagnostic equipment including oscilloscopes, power analyzers, and ultrasonic thickness gauges provide detailed analysis capabilities for complex problems requiring professional expertise.

Portable diagnostic equipment enables field testing and troubleshooting without removing components from service, minimizing downtime while providing accurate condition assessment.

Measurement Documentation and Trending

Systematic documentation of measurements and observations creates valuable trending data for predictive maintenance programs. Consistent measurement procedures and recording methods ensure data accuracy and comparability over time.

Digital data collection systems eliminate transcription errors while providing automatic trending and alarm capabilities. Integration with computerized maintenance management systems (CMMS) enables comprehensive maintenance program management.

Historical data analysis reveals patterns and correlations that improve diagnostic accuracy while optimizing maintenance intervals based on actual equipment performance rather than generic recommendations.

Professional Component Assessment Services

When component issues exceed internal diagnostic capabilities, professional assessment services provide expert analysis and recommendations. Centerless Grinding Solutions offers comprehensive diagnostic services including vibration analysis, thermal imaging, and component inspection programs.

Our experienced technicians utilize advanced diagnostic equipment and decades of centerless grinding experience to identify problems accurately while recommending cost-effective solutions. We provide component rebuilding services that restore original performance specifications while upgrading outdated designs.

For businesses requiring ongoing support, our preventive maintenance programs include regular inspections, diagnostic testing, and component monitoring to prevent unexpected failures while optimizing equipment performance.

Cost Analysis: Preventive vs. Reactive Maintenance

Financial Impact of Component Failures

Unplanned component failures cost significantly more than preventive maintenance through production losses, emergency repair premiums, and secondary damage to related components. Emergency repairs typically cost 3-5 times more than planned maintenance while causing substantial production disruption.

Production losses during unplanned downtime often exceed repair costs, particularly in high-value manufacturing operations where hourly production rates justify substantial preventive maintenance investments.

Secondary damage from component failures can affect multiple systems, turning simple bearing replacements into major rebuilds involving spindles, housings, and related components.

Return on Investment for Monitoring Programs

Systematic component monitoring programs typically provide 3:1 to 10:1 return on investment through prevented failures, optimized maintenance timing, and extended component life. Investment in diagnostic equipment and training pays for itself through reduced maintenance costs and improved equipment availability.

Predictive maintenance enables optimal component replacement timing, maximizing useful life while preventing unexpected failures. This approach reduces both maintenance costs and inventory requirements compared to time-based replacement strategies.

Improved equipment reliability through proactive component management increases production capacity and quality consistency, providing additional value beyond direct maintenance cost savings.

Contact Centerless Grinding Solutions Today

Experiencing component issues with your centerless grinder? Contact Centerless Grinding Solutions for professional diagnostic services and expert component assessment. Our experienced technicians provide comprehensive troubleshooting services that identify problems accurately while recommending cost-effective solutions. Schedule your component evaluation today and discover how proactive maintenance transforms your grinding operations while preventing costly unexpected failures.