Total Cost of Ownership for Centerless Grinding Equipment

Equipment purchasing decisions based solely on initial price often result in higher long-term costs and reduced profitability. Total cost of ownership (TCO) for centerless grinding equipment averages 3-5 times the initial purchase price over typical 15-20 year service life, making comprehensive cost analysis essential for optimal investment decisions. Smart manufacturers use systematic TCO calculations to evaluate equipment investments while maximizing return on investment through informed decision-making.

Hidden costs including maintenance, energy consumption, downtime, and operator training significantly impact long-term profitability beyond initial equipment pricing. Understanding complete ownership costs enables accurate ROI calculations that identify the most cost-effective equipment solutions for specific manufacturing requirements.

What is Total Cost of Ownership for Centerless Grinding Equipment?

TCO represents all costs associated with acquiring, operating, and maintaining centerless grinding equipment throughout its useful service life, including purchase price, installation, training, maintenance, energy, and disposal costs.

TCO analysis considers both direct costs (purchase price, maintenance, energy) and indirect costs (downtime losses, quality issues, opportunity costs) that affect equipment profitability over time. Comprehensive TCO evaluation reveals true investment value beyond initial purchase considerations.

Equipment lifecycle costs typically break down as: 20-25% acquisition costs, 35-40% maintenance and repairs, 25-30% energy and consumables, 10-15% downtime and productivity losses, with remaining costs from training, disposal, and financing.

Critical Cost Components in Centerless Grinder TCO Analysis

Understanding these cost elements ensures comprehensive investment evaluation:

- Initial equipment purchase price and financing costs

- Installation and setup expenses including utilities and foundations

- Operator training and certification requirements

- Preventive maintenance scheduling and costs

- Repair and rebuild expenses over equipment lifetime

- Energy consumption for operation and auxiliary systems

- Tooling and consumables including wheels and coolants

- Downtime costs from maintenance and repairs

- Quality-related expenses from scrap and rework

- End-of-life disposal and equipment replacement costs

Centerless Grinding Equipment Purchase Price and Setup Costs

Equipment Acquisition Cost Analysis

Equipment acquisition costs include base machine price, optional features, delivery, and installation expenses that establish the foundation for TCO calculations. Premium equipment typically costs 20-40% more initially but often provides superior long-term value through reduced maintenance and higher productivity.

Financing considerations including interest rates, payment terms, and tax implications affect total acquisition costs significantly. Lease versus purchase analysis should consider tax benefits, cash flow requirements, and equipment upgrade strategies when evaluating financing options.

Optional equipment features and automation capabilities require cost-benefit analysis to determine value over equipment lifetime. Advanced controls, automation systems, and precision options may justify higher initial costs through productivity improvements and reduced labor requirements.

Centerless Grinder Installation and Infrastructure Requirements

Installation expenses often represent 15-25% of equipment cost through foundation work, utility connections, safety systems, and initial setup requirements. Proper planning minimizes installation costs while ensuring optimal equipment performance from startup.

Facility modifications including electrical upgrades, compressed air systems, coolant infrastructure, and ventilation requirements add substantial costs beyond basic equipment pricing. Early infrastructure planning prevents unexpected expenses during installation.

Training and startup assistance ensure optimal equipment utilization from initial operation while preventing costly mistakes during the learning curve. Professional installation and training services provide long-term value through proper equipment setup and operator competence.

Operating Costs for Centerless Grinding Machines

Energy Consumption and Efficiency in Grinding Operations

Energy costs represent significant ongoing expenses throughout equipment lifetime, with efficient machines providing substantial savings over less efficient alternatives. Modern centerless grinders consume 20-40% less energy than older designs through improved motor efficiency and optimized hydraulic systems.

Power consumption varies significantly based on spindle power, hydraulic requirements, coolant systems, and automation features. Understanding specific energy requirements enables accurate cost projections while identifying opportunities for efficiency improvements.

Utility rate structures including demand charges, time-of-use pricing, and power factor penalties affect total energy costs beyond simple consumption calculations. Working with utility providers helps optimize operating schedules while minimizing energy expenses.

Centerless Grinder Maintenance Cost Planning

Preventive maintenance represents 60-70% of total maintenance costs but prevents expensive emergency repairs and extends equipment lifetime significantly. Systematic maintenance planning optimizes service intervals while minimizing both planned and unplanned maintenance expenses.

Component replacement schedules based on manufacturer recommendations and actual operating conditions help predict maintenance costs accurately while preventing unexpected failures. Major components including spindles, hydraulic pumps, and control systems require periodic rebuilding or replacement.

Maintenance labor costs vary significantly based on internal capabilities versus contracted services. Developing internal maintenance expertise reduces long-term costs while improving response times for routine service requirements.

Productivity Impact and Downtime Costs in Grinding Operations

Production Efficiency and Equipment Performance

Equipment productivity directly affects manufacturing costs through cycle times, quality consistency, and overall equipment effectiveness (OEE). High-performance centerless grinders achieve 85-95% OEE compared to 60-75% for older or poorly maintained equipment, significantly impacting profitability.

Cycle time improvements from modern equipment reduce per-part processing costs while increasing production capacity. Automation features including automatic loading, in-process gauging, and integrated quality control further improve productivity and reduce labor costs.

Quality consistency affects productivity through reduced scrap rates, rework requirements, and customer satisfaction. Superior equipment typically produces higher quality parts with greater consistency, reducing quality-related costs significantly.

Calculating Downtime Costs for Centerless Grinding Equipment

Unplanned downtime costs average $50,000-$100,000 per hour for high-volume manufacturing operations, making equipment reliability critical for cost control. Reliable equipment with predictable maintenance requirements minimizes unplanned downtime while enabling efficient production scheduling.

Planned maintenance downtime affects production schedules but enables optimization through coordination with production requirements. Modern equipment often features quick-change capabilities and modular designs that minimize maintenance downtime.

Spare parts availability and service response times directly impact downtime duration and associated costs. Equipment manufacturers with comprehensive parts support and local service capabilities provide superior long-term value through reduced downtime exposure.

Frequently Asked Questions About Centerless Grinding Equipment TCO and ROI

How long should centerless grinding equipment last? Quality centerless grinders typically provide 15-20 years of productive service with proper maintenance, though some machines operate effectively for 25+ years with appropriate rebuilding and modernization.

What percentage of TCO is the initial purchase price? Initial purchase price typically represents 20-25% of total cost of ownership, with operating costs including maintenance, energy, and consumables comprising the majority of lifetime expenses.

How do I calculate ROI for grinding equipment investments? Calculate ROI by comparing annual benefits (productivity gains, quality improvements, cost reductions) against total annual costs including depreciation, financing, and operating expenses.

What factors most impact centerless grinding equipment TCO? Reliability, energy efficiency, maintenance requirements, and productivity capabilities have the greatest impact on total cost of ownership over equipment lifetime.

Should I buy new or used centerless grinding equipment? New equipment offers latest technology and full warranties but costs more initially. Used equipment costs less upfront but may have higher maintenance costs and shorter remaining life.

How can I reduce centerless grinding equipment operating costs? Reduce costs through preventive maintenance programs, energy efficiency upgrades, operator training, quality improvement initiatives, and systematic process optimization.

ROI Calculation Methods for Centerless Grinding Investments

Financial Analysis Framework for Equipment Investments

Return on investment calculations compare annual benefits against total annual costs including depreciation, financing, operating expenses, and opportunity costs. Comprehensive ROI analysis considers both quantifiable benefits and strategic value from equipment investments.

Payback period analysis determines how quickly equipment investments recover initial costs through productivity improvements, cost reductions, and quality enhancements. Typical centerless grinding equipment payback periods range from 2-5 years depending on application requirements.

Net present value (NPV) calculations account for time value of money when evaluating equipment investments over extended periods. NPV analysis helps compare different investment alternatives while considering financing costs and inflation effects.

Quantifying Benefits from Centerless Grinding Equipment

Productivity improvements through faster cycle times, higher quality output, and reduced labor requirements provide quantifiable benefits that justify equipment investments. Modern equipment often improves productivity 25-40% compared to older alternatives through advanced technology and automation.

Quality improvements reducing scrap rates, rework costs, and customer complaints provide substantial long-term benefits that may exceed direct productivity gains. Superior equipment consistency eliminates quality-related expenses while improving customer satisfaction.

Maintenance cost reductions from reliable equipment with predictable service requirements provide ongoing savings throughout equipment lifetime. Modern equipment typically requires 30-50% less maintenance than older alternatives through improved design and component quality.

New vs. Remanufactured Centerless Grinding Equipment Costs

New Centerless Grinder Investment Value

New centerless grinding equipment offers latest technology, full manufacturer warranties, and longest service life potential. New equipment typically provides 15-20 year service life with predictable maintenance requirements and comprehensive support from manufacturers.

Advanced features including CNC controls, automation capabilities, and energy efficiency improvements justify higher initial costs through improved productivity and reduced operating expenses. Modern equipment often pays for itself through efficiency gains within 3-5 years.

Financing options for new equipment typically offer favorable terms and tax benefits that improve overall investment returns. Manufacturer support including training, service, and parts availability provides additional value throughout equipment lifetime.

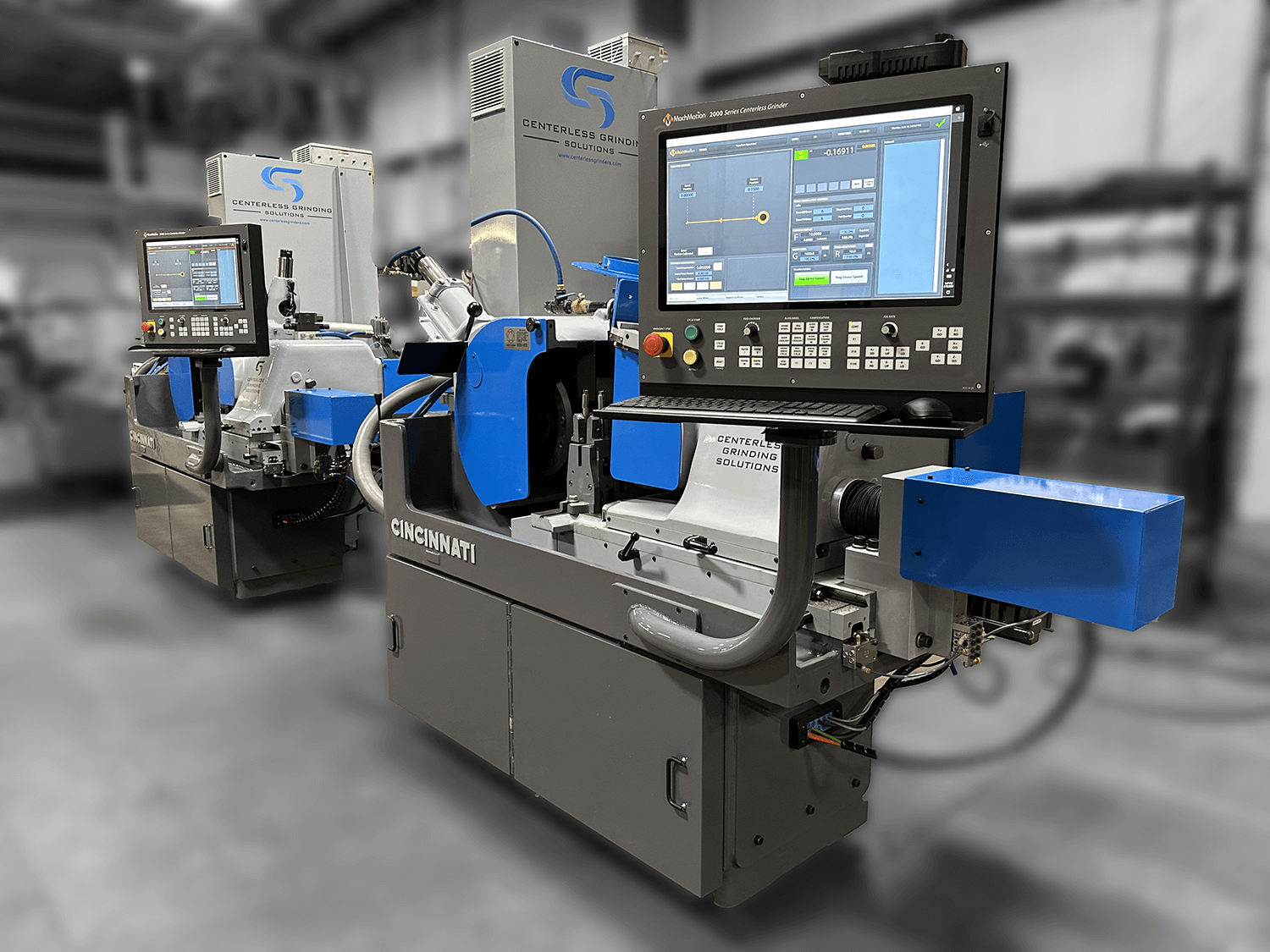

Remanufactured Centerless Grinder Cost Analysis

Remanufactured equipment costs 40-60% less than new while providing 80-90% of original performance capabilities through professional rebuilding processes. Quality remanufacturing restores equipment to near-original specifications with updated components and controls.

Shorter delivery times for remanufactured equipment enable faster production improvements compared to new equipment with 6-12 month lead times. Immediate availability helps address urgent capacity requirements or equipment replacement needs.

Proven performance history of remanufactured machines reduces risk compared to new equipment designs that lack field experience. Established maintenance procedures and parts availability provide operational advantages.

Technology Impact on Centerless Grinding Equipment Value

Automation and CNC Control System ROI

Modern control systems provide precision, repeatability, and data collection capabilities that improve quality while reducing labor requirements. CNC controls typically improve part consistency 50-70% compared to manual operations while enabling lights-out manufacturing capabilities.

Automation features including automatic loading, in-process gauging, and quality monitoring reduce labor costs while improving productivity and consistency. Advanced automation pays for itself through labor savings and quality improvements within 2-3 years typically.

Data collection and analysis capabilities enable predictive maintenance, process optimization, and quality tracking that provide ongoing benefits throughout equipment lifetime. Connected equipment supports Industry 4.0 initiatives while improving operational efficiency.

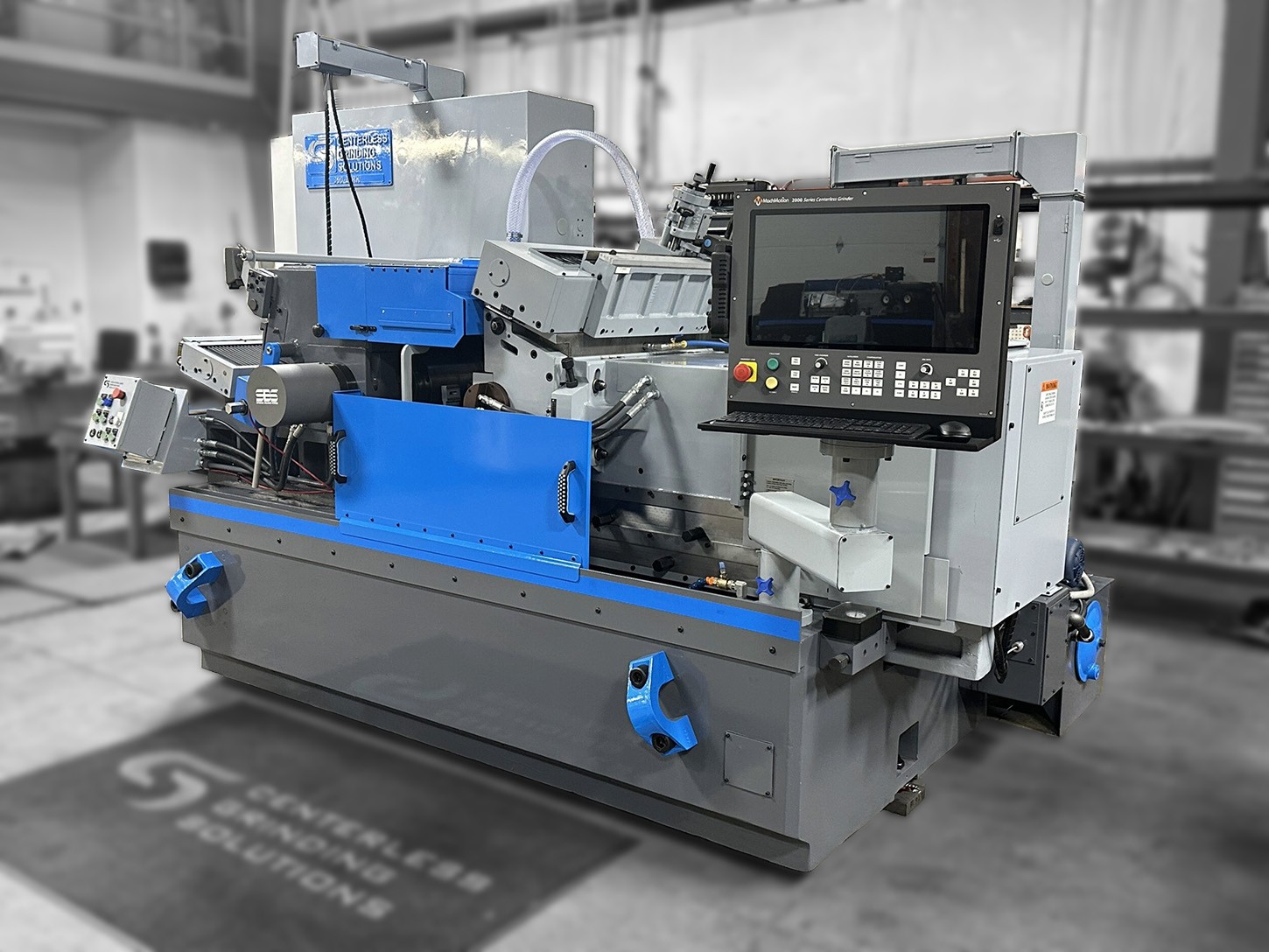

Professional TCO Analysis and Equipment Evaluation Services

When equipment investment decisions exceed internal analysis capabilities, professional consulting services provide expert evaluation and recommendations. Centerless Grinding Solutions offers comprehensive TCO analysis including cost modeling, ROI calculations, and equipment comparison services.

Our experienced team understands the complex relationships between equipment capabilities, operating costs, and production requirements. We provide equipment evaluation services that identify optimal solutions while maximizing long-term value.

For businesses considering equipment upgrades, our modernization consulting services analyze retrofit opportunities versus new equipment investments, helping optimize capital allocation while achieving performance objectives.

Capital Equipment Budget Planning for Centerless Grinders

Strategic Equipment Investment Planning

Strategic equipment planning aligns investments with business objectives while optimizing timing and funding sources. Multi-year equipment plans enable budget allocation while taking advantage of favorable market conditions and financing opportunities.

Equipment replacement schedules based on TCO analysis and production requirements help optimize timing while avoiding emergency purchases at premium pricing. Planned replacements enable thorough evaluation and negotiation for optimal terms.

Budgeting for unexpected equipment needs through contingency planning prevents production disruptions while maintaining cost control. Emergency equipment funds enable rapid response to equipment failures without compromising other investments.

Cost Control Strategies for Grinding Operations

Systematic cost tracking and analysis identify opportunities for ongoing cost reductions through process optimization, maintenance improvements, and operational efficiency gains. Regular cost reviews ensure equipment continues meeting financial objectives.

Vendor partnerships and service agreements provide predictable costs while ensuring optimal equipment performance throughout service life. Strategic partnerships often provide cost advantages while improving service quality and response times.

Maximize ROI Through Comprehensive Centerless Grinding Equipment TCO Analysis

Total cost of ownership analysis for centerless grinding equipment investments requires systematic evaluation of all lifecycle costs including acquisition, operation, maintenance, and disposal expenses that impact long-term profitability. Through comprehensive TCO calculations and ROI analysis, manufacturers identify optimal equipment solutions that maximize productivity while minimizing total ownership costs. Advanced equipment features including automation, energy efficiency, and reliability improvements often justify higher initial costs through superior long-term value and reduced operating expenses.

Professional TCO analysis and financial planning services provide expert guidance for complex equipment investments while ensuring alignment with business objectives and available capital resources. By implementing systematic equipment evaluation procedures and understanding true ownership costs, manufacturing operations achieve optimal equipment investments that support competitive success while maximizing return on investment.

Ready to optimize your centerless grinding equipment investment?

Contact Centerless Grinding Solutions for comprehensive TCO analysis and professional equipment evaluation services. Our experienced team provides detailed cost modeling, ROI calculations, and investment recommendations that maximize long-term value while meeting your production requirements. Schedule your equipment investment consultation today and discover how proper TCO analysis transforms your equipment decisions while ensuring optimal returns.