Retrofitting Older Centerless Grinders: What You Need to Know for Maximum ROI

When your centerless grinder shows signs of age but the fundamental machine structure remains sound, retrofitting presents an excellent opportunity to modernize capabilities while avoiding the substantial cost of new equipment. Centerless grinder retrofitting can extend machine life by 15-20 years while incorporating modern control systems, improved safety features, and enhanced precision capabilities that rival new machines.

Understanding Centerless Grinder Retrofit Opportunities

Retrofitting involves systematically upgrading key components of your existing centerless grinder to restore performance and add modern capabilities. Unlike basic repairs that address immediate problems, comprehensive retrofits transform older machines into reliable, productive assets that meet current manufacturing demands.

The most common retrofit candidates include machines manufactured between 1970-2000 that feature solid mechanical construction but outdated control systems, worn spindle assemblies, or obsolete safety systems. These machines often represent significant value because their fundamental design and construction quality exceed many newer, budget-oriented alternatives.

Successful retrofitting requires evaluating both the machine’s current condition and your production requirements. Machines with excessive bed wear, cracked castings, or severely damaged spindle housings may not justify retrofit investment compared to remanufactured alternatives.

Essential Components for Centerless Grinder Modernization

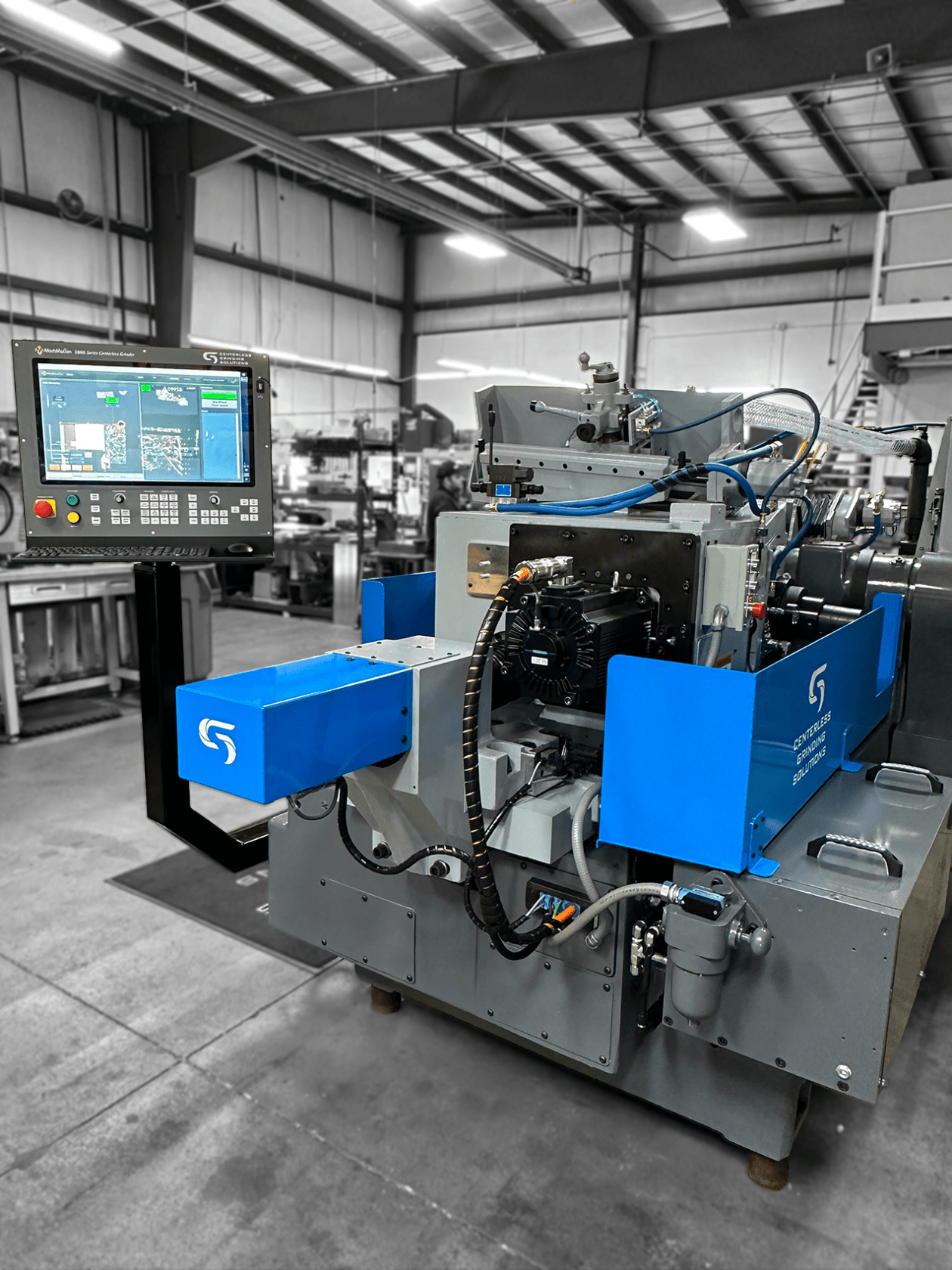

Advanced Control System Upgrades

Modern CNC controls represent the most transformative retrofit upgrade for older centerless grinders. Upgrading from manual or basic semi-automatic controls to modern CNC systems can improve part consistency, reduce setup time, and enable lights-out operation for suitable applications.

Contemporary control systems offer programmable grinding cycles, automatic wheel dressing routines, and integrated process monitoring that was unavailable when older machines were manufactured. These capabilities translate directly into improved part quality, reduced operator workload, and enhanced production flexibility.

Touch-screen interfaces replace complex mechanical controls, making machine operation more intuitive while providing detailed process feedback. Modern controls also enable data collection for statistical process control and predictive maintenance programs.

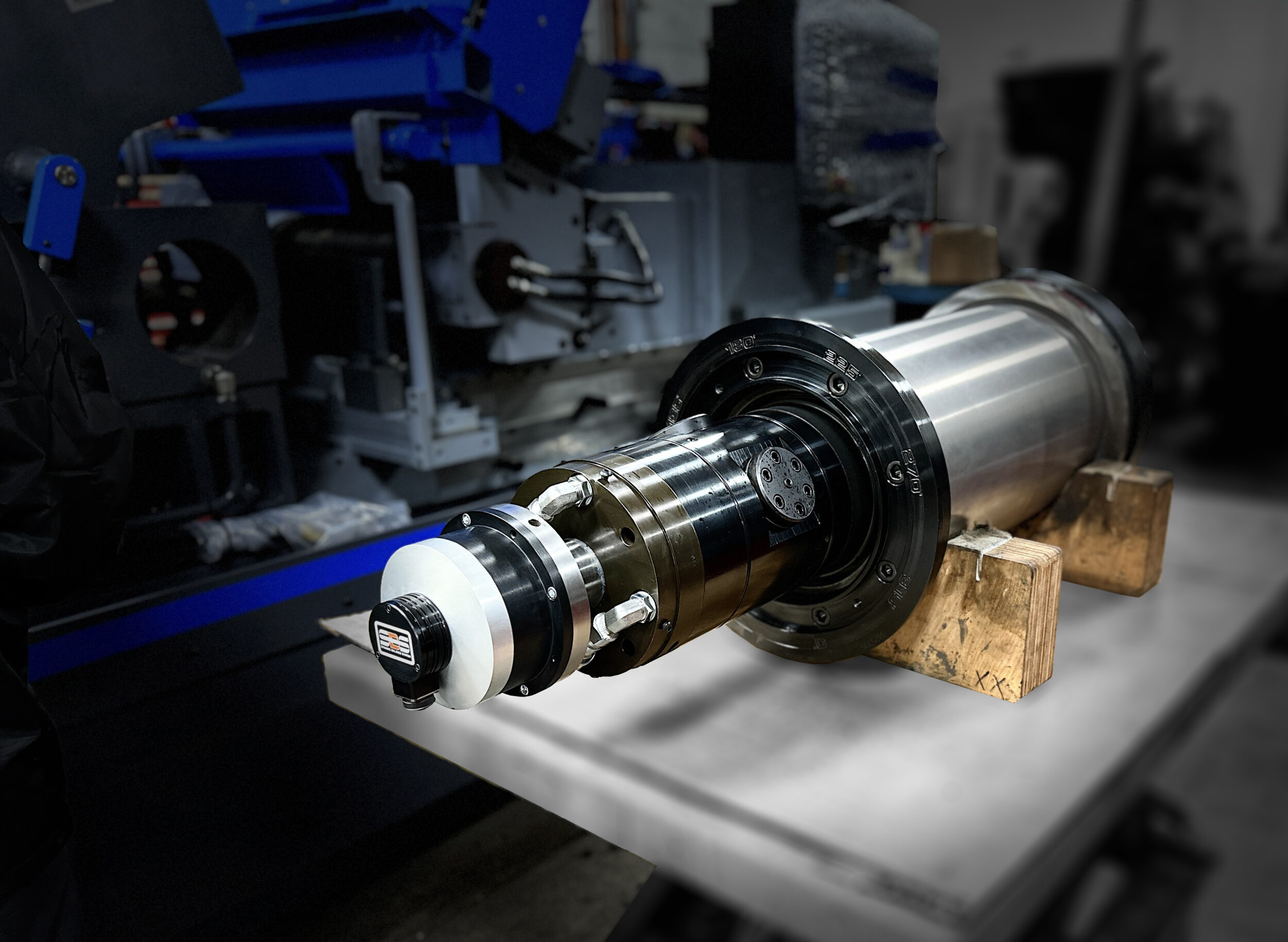

Spindle Assembly Restoration and Upgrades

Spindle assemblies represent the heart of centerless grinder performance, and retrofit programs often include complete spindle rebuilding or replacement. High-precision spindle restoration can achieve original equipment specifications while incorporating improved bearing technology and enhanced vibration dampening.

Upgraded spindle assemblies may feature ceramic or hybrid bearings that offer extended service life and improved thermal stability compared to original steel bearings. Advanced lubrication systems with temperature and pressure monitoring help prevent premature bearing failure while extending maintenance intervals.

Balancing precision becomes critical during spindle restoration, as modern production requirements often exceed original equipment specifications. Professional spindle rebuilding ensures dynamic balance meets contemporary standards while maintaining the structural integrity essential for heavy grinding operations.

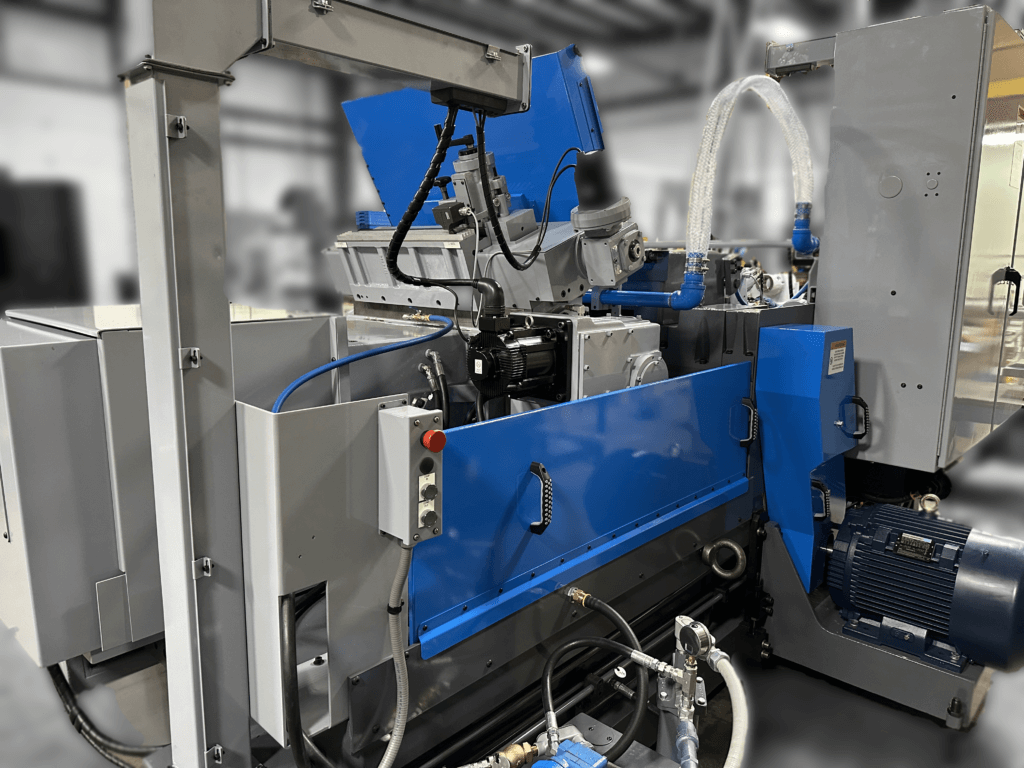

Safety System Integration

Older centerless grinders typically lack modern safety features now required by current OSHA standards and best practices. Retrofit safety upgrades protect operators while ensuring regulatory compliance and reducing insurance liability.

Essential safety retrofits include emergency stop systems, light curtains or safety gates, and interlocked guards that prevent access to moving components during operation. Modern safety systems integrate with machine controls to provide coordinated protection without impeding normal operation.

Ergonomic improvements, including adjustable work surfaces and improved lighting, enhance operator comfort while reducing fatigue-related errors. These upgrades contribute directly to productivity improvements and worker satisfaction.

Evaluating Your Centerless Grinder for Retrofit Potential

Mechanical Condition Assessment

Professional evaluation of your machine’s mechanical condition determines retrofit feasibility and helps prioritize upgrade components. Key assessment areas include bed condition, spindle housing integrity, and overall structural soundness.

Bed wear patterns indicate how the machine has been used and maintained throughout its service life. Excessive wear may require bed grinding or replacement, significantly impacting retrofit costs. However, minor wear often can be compensated through proper setup and alignment procedures.

Spindle housing condition affects the success of spindle upgrades, as housing damage can compromise bearing installation and alignment. Professional assessment identifies potential issues before retrofit work begins, preventing costly surprises during the upgrade process.

Foundation and mounting systems require evaluation to ensure they can support upgraded components and maintain precision during operation. Older installations may need foundation improvements to achieve optimal performance from retrofitted equipment.

Production Requirements Analysis

Understanding your current and future production requirements guides retrofit decision-making and component selection. Analyze part mix, volume requirements, and precision specifications to determine which upgrades provide the greatest return on investment.

High-volume production benefits most from automation upgrades, including automatic loading systems and integrated quality monitoring. Lower volume, high-mix production may prioritize quick-change tooling and flexible setup capabilities over full automation.

Precision requirements influence spindle upgrade specifications and control system selection. Applications requiring sub-micron tolerances justify premium components, while general production work may achieve acceptable results with more economical upgrade options.

Cost-Benefit Analysis of Centerless Grinder Retrofitting

Investment Comparison: Retrofit vs. New Equipment

Comprehensive retrofitting typically costs 40-60% of new equipment pricing while delivering 80-90% of new machine capabilities. This cost advantage makes retrofitting attractive for businesses seeking to modernize capabilities without major capital expenditure.

New equipment offers latest technology and full warranty coverage but requires substantially higher initial investment. Retrofit projects provide proven machine foundations with modern capabilities at significantly reduced cost, though warranty coverage may be more limited.

Delivery timelines favor retrofitting, as most projects complete within 8-16 weeks compared to 6-12 months for new equipment. This shorter timeline reduces production disruption and accelerates return on investment.

Return on Investment Calculations

ROI calculations should include productivity improvements, quality enhancements, and reduced maintenance costs achievable through retrofitting. Modern controls typically improve cycle times by 15-25% while reducing scrap rates through better process control.

Energy efficiency improvements from modern spindle drives and control systems reduce operating costs throughout the machine’s extended service life. LED lighting upgrades and efficient hydraulic systems contribute to ongoing operational savings.

Reduced maintenance requirements from upgraded components lower long-term operating costs while improving machine availability. Modern diagnostic capabilities enable predictive maintenance that prevents costly unplanned downtime.

Working with Professional Retrofit Specialists

Selecting Qualified Retrofit Partners

Choose retrofit specialists with extensive centerless grinding experience and proven track records with your specific machine models. Experienced partners understand the unique challenges and opportunities associated with different manufacturer designs and vintage equipment.

Comprehensive retrofit capabilities should include mechanical rebuilding, electrical upgrades, and integration services that ensure all systems work together effectively. Single-source responsibility simplifies project management while ensuring compatibility between upgraded components.

Reference projects and customer testimonials provide insight into retrofit specialist capabilities and customer satisfaction levels. Direct communication with previous customers offers valuable perspective on project execution and long-term results.

Project Planning and Implementation

Successful retrofit projects require detailed planning that addresses production scheduling, component procurement, and installation logistics. Professional project management ensures minimal production disruption while maintaining upgrade quality and timeline adherence.

Pre-retrofit evaluation establishes baseline performance measurements that enable objective assessment of improvement results. Documentation of existing conditions also helps identify potential complications before work begins.

Installation scheduling should accommodate your production requirements while allowing adequate time for proper testing and optimization. Rushed installations compromise upgrade quality and may create long-term reliability issues.

Maximizing Retrofit Success and Long-Term Performance

Post-retrofit optimization ensures your upgraded centerless grinder achieves maximum performance potential. Proper operator training on new control systems and capabilities is essential for realizing retrofit benefits while maintaining safe operation.

Preventive maintenance programs should be updated to reflect upgraded components and their specific requirements. Modern diagnostic capabilities enable condition-based maintenance that optimizes component life while preventing unexpected failures.

Performance monitoring during the initial operating period helps identify optimization opportunities and ensures all systems function as intended. Professional support during this period accelerates the learning curve and maximizes retrofit investment returns.

Transform Your Production Capabilities With Centerless Grinding Solutions

Centerless Grinding Solutions offers manufacturers a proven path to modernize aging equipment while maximizing return on investment. By upgrading essential components like control systems, spindle assemblies, and safety features, businesses can extend machine life by 15-20 years at 40-60% the cost of new equipment. The key to successful retrofitting lies in thorough mechanical assessment, clear production requirements analysis, and partnership with experienced specialists who understand centerless grinding technology. With proper planning and implementation, retrofitted centerless grinders deliver 80-90% of new machine capabilities while reducing project timelines and capital expenditure, making this modernization strategy an intelligent choice for manufacturers seeking competitive advantages in precision grinding operations.