How to Fix Common Centerless Grinding Defects

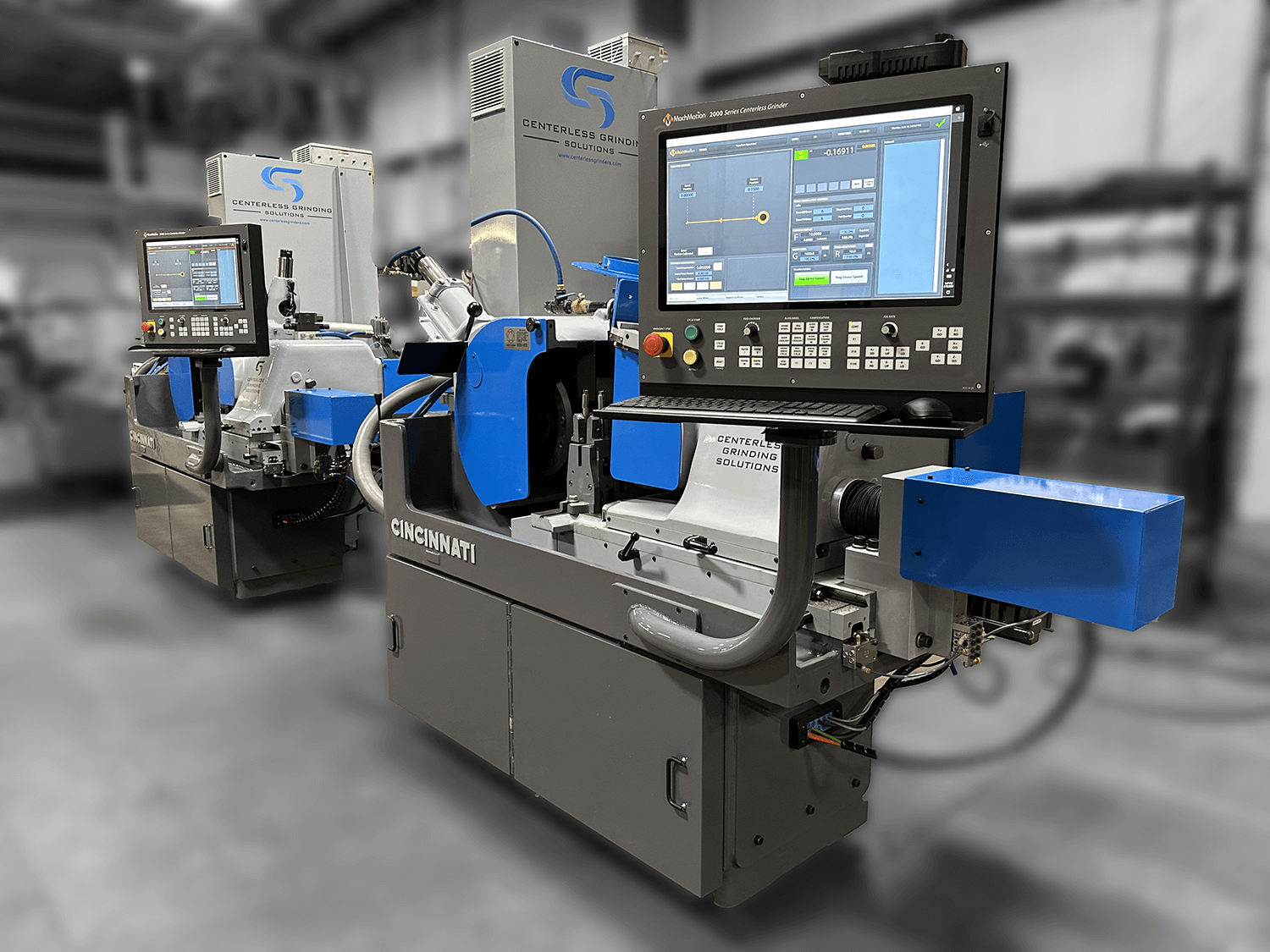

Centerless grinding defects can shut down your job shop operation and cost thousands in scrapped parts. As maintenance managers and plant supervisors know, identifying the root cause quickly makes the difference between minor adjustments and major production losses. After 30+ years specializing in Cincinnati centerless grinders here in Ohio, we’ve seen every defect pattern and know exactly how to fix them.

Most grinding defects stem from three main areas: machine setup issues, worn components, or improper grinding parameters. The good news? Nearly all problems are preventable with the right knowledge and quick corrective action.

Understanding Centerless Grinding Defect Types

Centerless grinding defects fall into three primary categories that maintenance teams encounter regularly:

Dimensional defects affect part size and geometry – including taper, out-of-round conditions, and size variations that push parts outside tolerance ranges.

Surface finish problems create visible issues like chatter marks, grinding burn, or rough finishes that fail quality inspection.

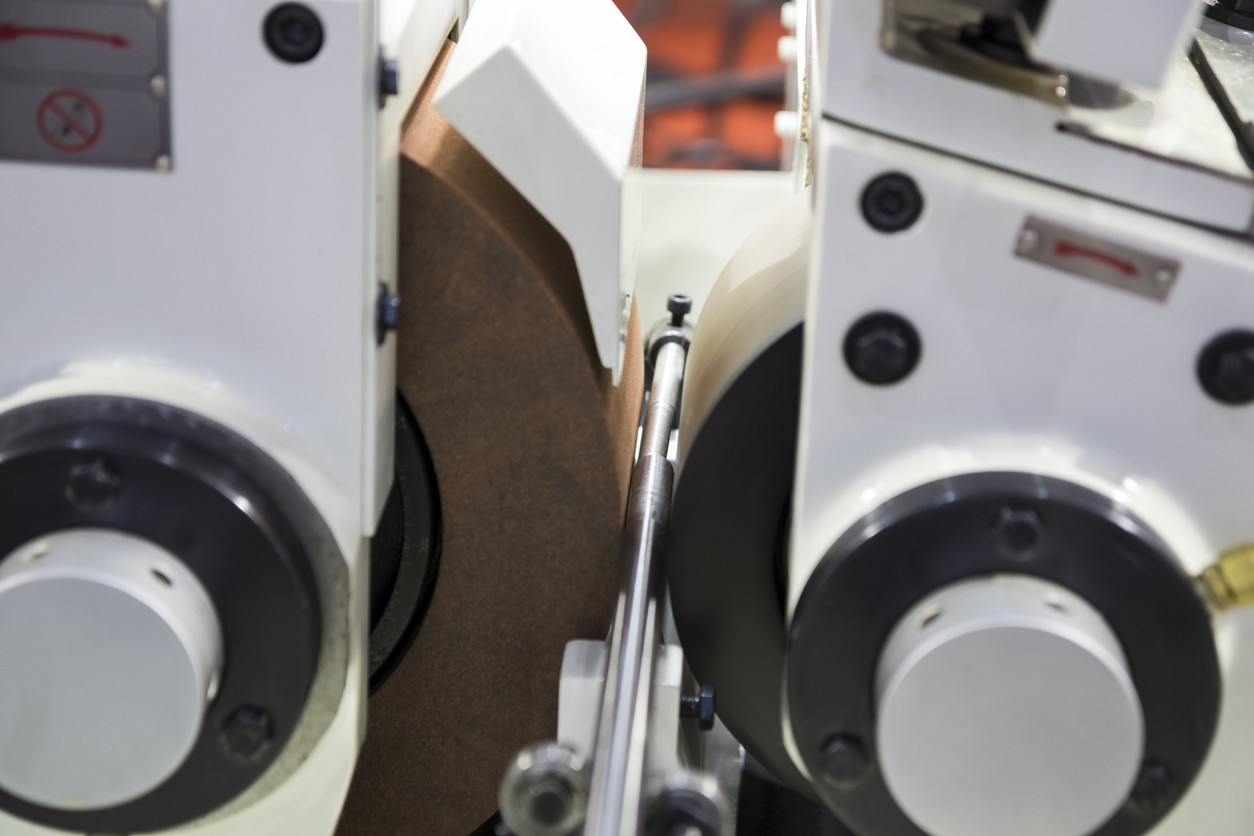

Setup-related defects occur from incorrect work rest blade positioning, improper wheel speeds, or alignment problems between grinding wheel and regulating wheel.

Early detection prevents entire batches from becoming scrap. Most job shop operations can resolve common defects in-house once they understand the specific cause-and-effect relationships.

Dimensional Problems: Taper and Size Issues

Fixing Taper in Cincinnati Centerless Grinders

Taper defects create parts that measure differently at each end – a common problem when grinding wheel and workpiece aren’t perfectly aligned. This issue frequently appears on older Cincinnati grinders where machine wear affects critical alignments.

Primary causes of taper:

Primary causes of taper include grinding wheel face not being parallel to work centerline, worn work rest blade creating uneven support across part length, machine bed wear affecting wheel alignment over time, and inadequate coolant causing thermal distortion during the grinding cycle. Each of these root causes creates characteristic taper patterns that experienced operators learn to recognize and correct systematically.

Step-by-step taper correction:

- Check grinding wheel alignment using a precision indicator across the wheel face

- Inspect work rest blade condition – look for wear patterns or height variations

- Verify machine bed condition – excessive wear requires professional attention

- Optimize coolant flow to prevent thermal expansion during grinding

Pro tip from our service team: On Cincinnati 220-8 grinders, taper often results from worn ways on the wheelhead. This requires professional rebuilding but catches many operators by surprise.

Eliminating Out-of-Round Conditions

Out-of-round parts fail geometric tolerances even when average diameter stays within spec. This defect typically indicates vibration or workpiece instability during grinding.

Common out-of-round causes:

Common out-of-round causes include worn or improperly positioned work rest blades that allow workpiece movement, grinding wheel imbalance or poor dressing creating irregular grinding forces, incorrect speed relationships between wheels affecting workpiece stability, and workpiece material inconsistencies that create varying grinding resistance. Understanding these relationships enables systematic problem diagnosis and correction.

Corrective actions:

- Replace worn work rest blades immediately

- Balance and dress grinding wheel properly

- Verify speed ratios match part material requirements

- Check incoming material for hardness variations

Surface Finish Defects: Chatter and Burn Marks

Stopping Chatter Marks on Ground Surfaces

Chatter appears as regular patterns on finished surfaces – either consistent spacing (indicating machine vibration) or random patterns (suggesting workpiece instability). This defect reduces surface quality and often leads to part rejection.

Chatter mark root causes:

Chatter mark root causes include grinding wheel out of balance or poorly dressed creating irregular grinding forces, worn spindle bearings allowing excessive vibration during operation, work rest blade positioned incorrectly affecting workpiece stability, and machine foundation problems or loose mounting allowing the entire machine structure to vibrate during grinding operations. Each cause creates characteristic chatter patterns that help identify the specific problem source.

Chatter elimination process:

- Balance the grinding wheel – most critical step for consistent results

- Dress the wheel properly using sharp diamond tools

- Check spindle bearing condition – listen for unusual noise or roughness

- Adjust work rest blade position to optimize workpiece support

- Verify machine mounting is secure and foundation is solid

Cincinnati grinder note: These machines often develop chatter when the original spindle bearings wear out. We stock replacement bearing sets for faster repairs.

Preventing Grinding Burn and Heat Damage

Grinding burn appears as blue, brown, or black discoloration indicating excessive heat during material removal. This thermal damage can create metallurgical changes that compromise part integrity.

Burn mark causes:

Burn mark causes include insufficient coolant flow or concentration failing to remove grinding heat effectively, dull or glazed grinding wheel creating excessive friction and heat generation, excessive grinding forces or feed rates removing material too aggressively, and wrong wheel specification for material creating improper grinding action that generates excess heat. Understanding these relationships enables systematic heat damage prevention.

Heat damage prevention:

- Increase coolant flow and verify concentration – most effective immediate fix

- Dress or replace grinding wheel if glazed or loaded

- Reduce feed rates to decrease heat generation

- Check wheel specification matches material hardness and finish requirements

Frequently Asked Questions About Centerless Grinding Defects

What causes the most common defects in job shop grinding operations? Work rest blade condition causes about 40% of defects we see in smaller operations. Worn blades create unstable workpiece support leading to chatter, out-of-round conditions, and size variations.

How do I know when grinding wheel problems cause defects versus machine issues? Wheel-related defects typically appear suddenly after wheel changes or dressing. Machine-related problems develop gradually and affect multiple wheels over time.

Can I prevent most defects with better maintenance? Regular work rest blade inspection, proper wheel dressing, and coolant system maintenance prevent most common defects. We recommend weekly blade checks and monthly coolant concentration testing.

What’s the fastest way to get replacement parts for Cincinnati grinders? We maintain inventory of critical Cincinnati grinder components including work rest blades, spindle parts, and control system elements. Most parts ship within 24 hours to Ohio and surrounding states.

Should I repair or replace my centerless grinder when defects become frequent? Consider professional remanufacturing when defects persist despite proper maintenance. A rebuilt machine often costs 50-70% less than new while providing decades of reliable service.

Stop Defects with Professional Cincinnati Grinder Support

Centerless grinding defects don’t have to shut down your operation or create expensive scrap. Understanding common defect patterns and their root causes enables quick corrections that keep production running smoothly.

Need immediate help with grinding defects? Contact Centerless Grinding Solutions for expert troubleshooting and fast parts delivery. Our Ohio-based team knows Cincinnati grinders inside and out, providing the technical support that keeps job shops productive.