Cincinnati Milacron Replacement Parts: Your Complete Guide to Equipment Longevity

When your Cincinnati Milacron centerless grinder experiences downtime, every minute counts. For manufacturers relying on these precision machines, having access to reliable Cincinnati Milacron replacement parts isn’t just convenient—it’s essential for maintaining production schedules and achieving the micron-level tolerances your operations demand.

With over 10,000 Cincinnati grinders still in operation across North America and equipment ages averaging 15-25 years, the need for quality replacement parts has never been greater. Understanding how to source, select, and maintain Cincinnati Milacron replacement parts can mean the difference between costly downtime and seamless operations.

Common Challenges When Sourcing Cincinnati Milacron Replacement Parts

Manufacturers operating Cincinnati Milacron centerless grinders often encounter unique obstacles that can significantly impact productivity and part quality.

Part Compatibility and Availability: Finding genuine or compatible replacement parts for Cincinnati grinders, especially older models, presents a persistent challenge. With Cincinnati equipment spanning multiple decades of manufacturing, ensuring perfect compatibility between replacement parts and your specific machine model requires specialized knowledge. Many manufacturers struggle to identify the exact part numbers needed or find suppliers who maintain comprehensive inventories of legacy components.

Material-Specific Performance Demands: Cincinnati Milacron grinders are renowned for their ability to handle challenging materials, but this capability depends entirely on having the right components. Workrest blades, grinding wheels, and regulating wheels must be precisely matched to the materials you’re processing. Using incorrect or substandard replacement parts can lead to inconsistent surface finishes, accelerated wear, and failure to meet tight tolerances.

Maintaining Precision Tolerances: Cincinnati equipment is prized for its ability to maintain micron-level accuracy, but this precision depends on every component working in perfect harmony. When replacement parts don’t meet original specifications, you risk thermal expansion issues, increased vibration, and gradual loss of accuracy that can compromise your entire production process.

Managing Wear and Replacement Cycles: The demanding nature of specialized grinding accelerates wear on critical Cincinnati Milacron replacement parts. Without a reliable parts supplier and proper inventory planning, unexpected failures can lead to extended downtime and rush orders at premium prices.

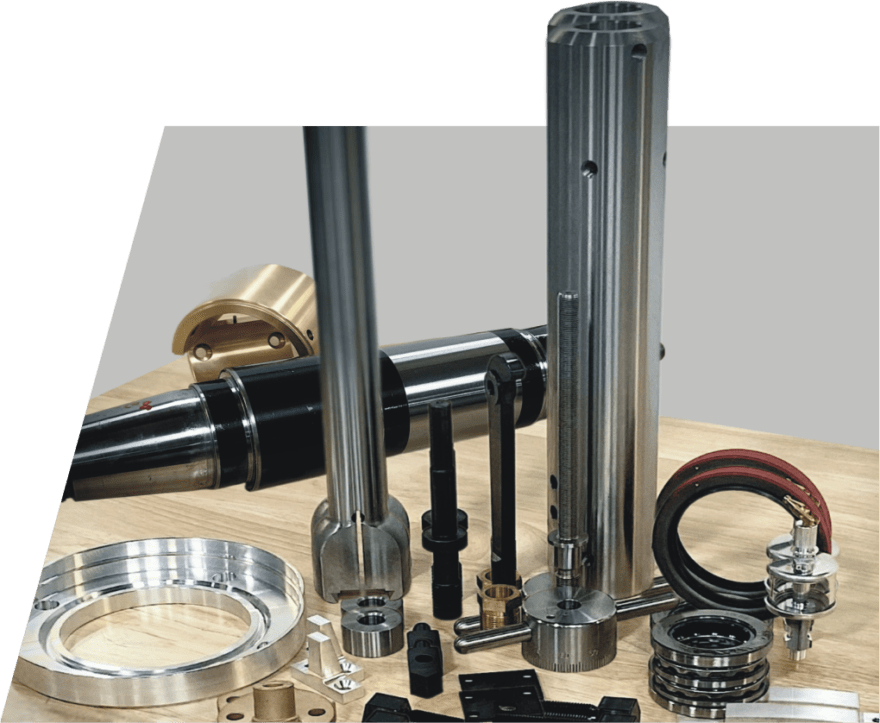

Essential Cincinnati Milacron Replacement Parts for Optimal Performance

The precision and reliability of your Cincinnati Milacron grinder depends on the quality and proper selection of its key components.

Workrest Blades: Acting as the critical support system during the grinding process, workrest blades directly influence part geometry and surface finish. High-quality replacement workrest blades maintain proper workpiece alignment, reducing the risk of taper or out-of-roundness. Specialized coatings and materials can dramatically improve wear resistance and extend blade life, making them one of the most important Cincinnati Milacron replacement parts to source correctly.

Spindle Assemblies: The spindle forms the heart of your Cincinnati grinder, directly impacting both accuracy and surface finish. Precision-engineered replacement spindle assemblies minimize runout to ensure consistent material removal rates. Robust designs that dampen vibrations become crucial for achieving and maintaining tight tolerances over extended production runs.

Regulating Wheels: These components control the speed and feed rate of your workpiece through the grinding process. The right regulating wheel material and design improve grip on challenging materials while ensuring consistent throughput, balancing aggressive material removal with the surface quality your applications demand.

Grinding Wheels: Directly impacting material removal rates and surface characteristics, grinding wheels represent one of the most frequently replaced components. Cincinnati-specific grinding wheel specifications ensure compatibility with your machine’s operating parameters. Specialized bonds and abrasives tailored to your materials and applications optimize performance and extend wheel life.

Control Systems and Sensors: Modern replacement controls and sensors for Cincinnati equipment allow for precise adjustments during grinding operations. Advanced sensor technology can detect and compensate for component wear, maintaining consistency throughout production runs and reducing scrap rates.

By investing in high-quality, Cincinnati-specific replacement parts, manufacturers can enhance grinding precision and repeatability, extend equipment lifespan, reduce maintenance downtime, and improve part quality and consistency even when processing challenging materials.

Maximizing Equipment Performance Through Expert Service

While sourcing quality Cincinnati Milacron replacement parts is essential, maximizing your equipment’s potential requires combining premium components with expert technical support.

Preventative Maintenance and Parts Management: Regular inspections identify potential issues before they escalate into costly failures. Scheduled maintenance keeps Cincinnati grinders operating at peak efficiency while extending the life of critical replacement parts. Proper lubrication schedules, alignment checks, and systematic parts replacement based on wear patterns prevent unexpected downtime.

Precision Calibration Services: Expert technicians ensure your Cincinnati equipment maintains its legendary micron-level accuracy through regular calibration. This process compensates for normal wear on Cincinnati Milacron replacement parts and environmental factors that affect precision, ensuring you’re getting maximum value from your parts investments.

Specialized Spindle Repair and Rebuilding: Cincinnati spindle assemblies represent sophisticated precision instruments requiring specialized knowledge for repair and rebuilding. Professional spindle services include precision balancing, runout correction, and upgrades to modern bearing technologies that improve both speed and accuracy. Expert rebuilding can restore performance that rivals new equipment at a fraction of the replacement cost.

Technical Training and Knowledge Transfer: Operator training tailored to Cincinnati equipment and specific grinding applications ensures your team understands proper setup, operation, and maintenance procedures. Training on Cincinnati Milacron replacement parts identification, installation, and troubleshooting empowers your staff to minimize downtime and extend component life.

Equipment Refurbishment and Modernization: Comprehensive refurbishment services breathe new life into aging Cincinnati equipment through systematic replacement of worn components and upgrades to modern control systems. This cost-effective alternative to purchasing new machinery allows you to preserve your investment while incorporating the latest grinding technologies, including CNC control retrofits and servo system conversions.

Why Choose Specialized Cincinnati Milacron Replacement Parts Suppliers

Not all replacement parts suppliers are created equal, especially when it comes to precision grinding equipment. Choosing a supplier who specializes in Cincinnati Milacron replacement parts offers distinct advantages:

Deep Equipment Knowledge: Specialists maintain comprehensive cross-reference databases for Cincinnati parts spanning decades of production. This institutional knowledge ensures you receive exactly the right components for your specific model, avoiding the trial-and-error approach that leads to costly mistakes and extended downtime.

Quality Assurance: Reputable Cincinnati parts specialists source components that meet or exceed original equipment specifications. Whether providing genuine Cincinnati Milacron replacement parts or high-quality compatible alternatives, specialized suppliers understand the performance standards required for precision grinding applications.

Inventory Depth and Availability: Specialists maintain extensive inventories of Cincinnati Milacron replacement parts, including hard-to-find components for legacy equipment. This inventory investment means faster turnaround times when you need parts urgently, minimizing costly production interruptions.

Comprehensive Support: Beyond parts supply, specialized Cincinnati suppliers offer technical support, installation guidance, and troubleshooting assistance. This comprehensive approach ensures you’re not just buying components but partnering with experts invested in your grinding success.

Conclusion: Protecting Your Cincinnati Milacron Investment

Your Cincinnati Milacron centerless grinder represents a significant capital investment and critical production asset. Success in specialized grinding depends on the synergy between high-quality replacement parts, expert knowledge, and ongoing support. The right partner can transform parts sourcing from a reactive burden into a competitive advantage, helping you achieve peak performance and extend equipment life for decades.

Contact Centerless Grinding Solutions today for a consultation on Cincinnati Milacron replacement parts, comprehensive service options, and equipment modernization. With over 35 years of specialized Cincinnati expertise, we help manufacturers across North America maximize their grinding equipment investments and achieve unparalleled precision in their manufacturing processes.