CNC Control Retrofit: Modernizing Centerless Grinding Operations

Centerless grinding has long been a cornerstone of precision manufacturing, shaping everything from automotive components to medical devices with unparalleled accuracy. However, as industries evolve and demand for higher precision and efficiency grows, traditional manual centerless grinding operations face increasing challenges:

- Inconsistency in output quality

- Inefficiency in production rates

- Heavy reliance on skilled operators

- Difficulty in meeting tighter tolerances

Enter control system modernization—a practical solution revolutionizing how job shops approach centerless grinding. By upgrading to CNC controls, servo systems, and modern HMI touchscreens, smaller manufacturers can transform aging equipment into precise, efficient machines capable of meeting today’s demanding specifications.

But what exactly do these upgrades entail, and how can they benefit your shop? How can you modernize your existing equipment without the massive investment of full automation?

In this article, we’ll explore the rise of control modernization in centerless grinding, its practical benefits for job shops, and real-world applications across various industries. Whether you’re a shop owner looking to extend equipment life or an engineer seeking better precision, understanding these upgrade options is crucial for staying competitive.

The Rise of Control Modernization in Centerless Grinding

Control modernization is more than updating old equipment—it’s about giving your existing centerless grinders the precision and reliability of modern machines without the cost of replacement.

What Control Modernization Means

Control modernization in centerless grinding encompasses targeted upgrades designed to improve precision, usability, and consistency while working with your existing equipment. Key upgrades include:

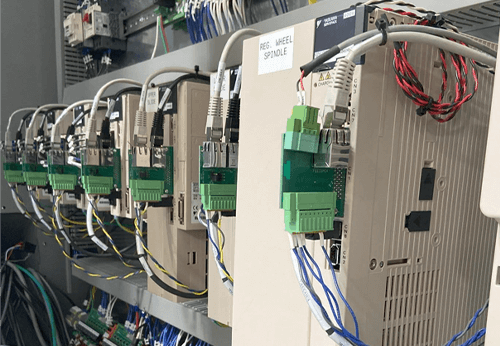

- CNC Control Retrofits: Replacing outdated relay logic and manual controls with modern CNC systems for precise, repeatable operations

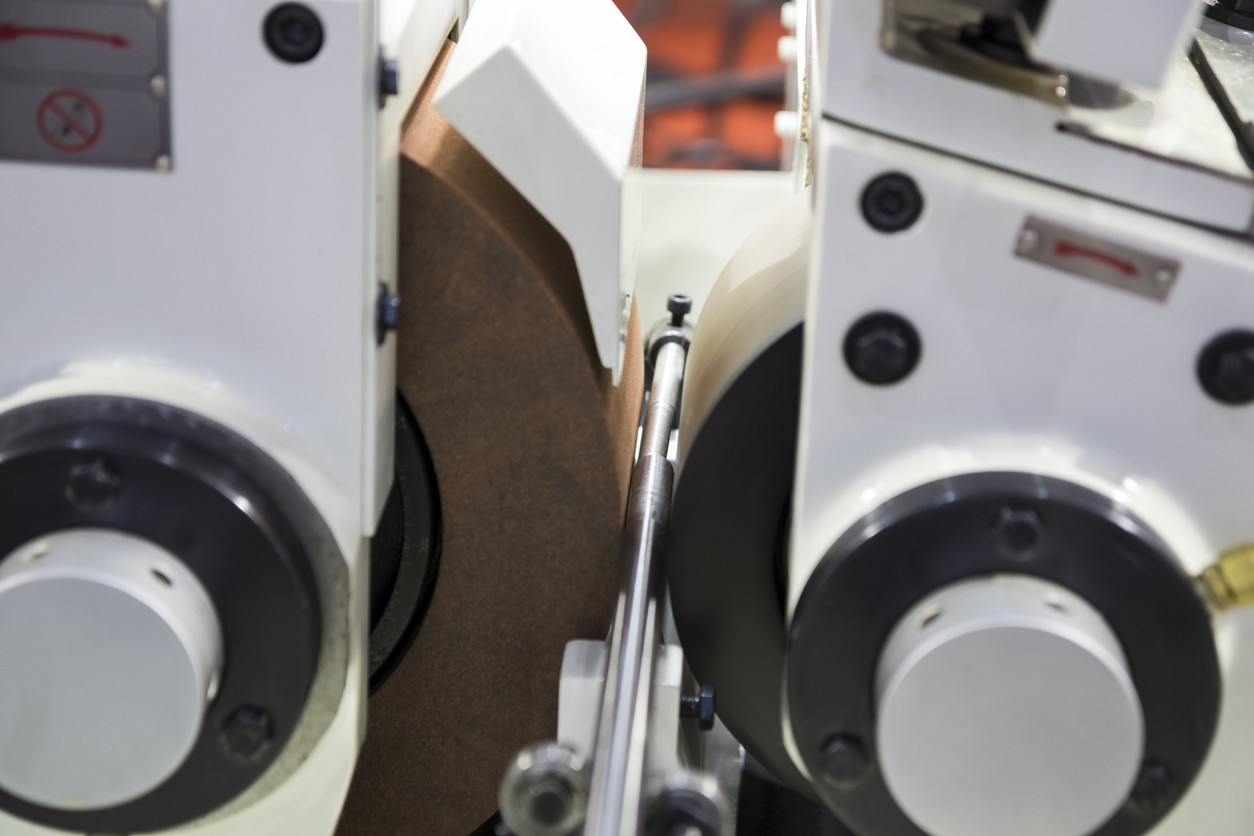

- Regulating Wheel Servo Conversion: Upgrading from manual or older control systems to precise servo-driven regulation for consistent part sizing

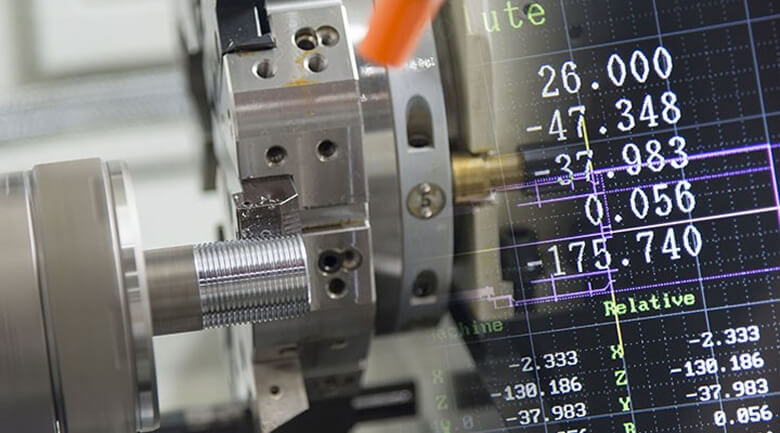

- HMI Touchscreen Modernization: Installing intuitive touchscreen interfaces that simplify operation and reduce setup time

- Control System Integration: Working with automation partners to integrate controls for improved workflow

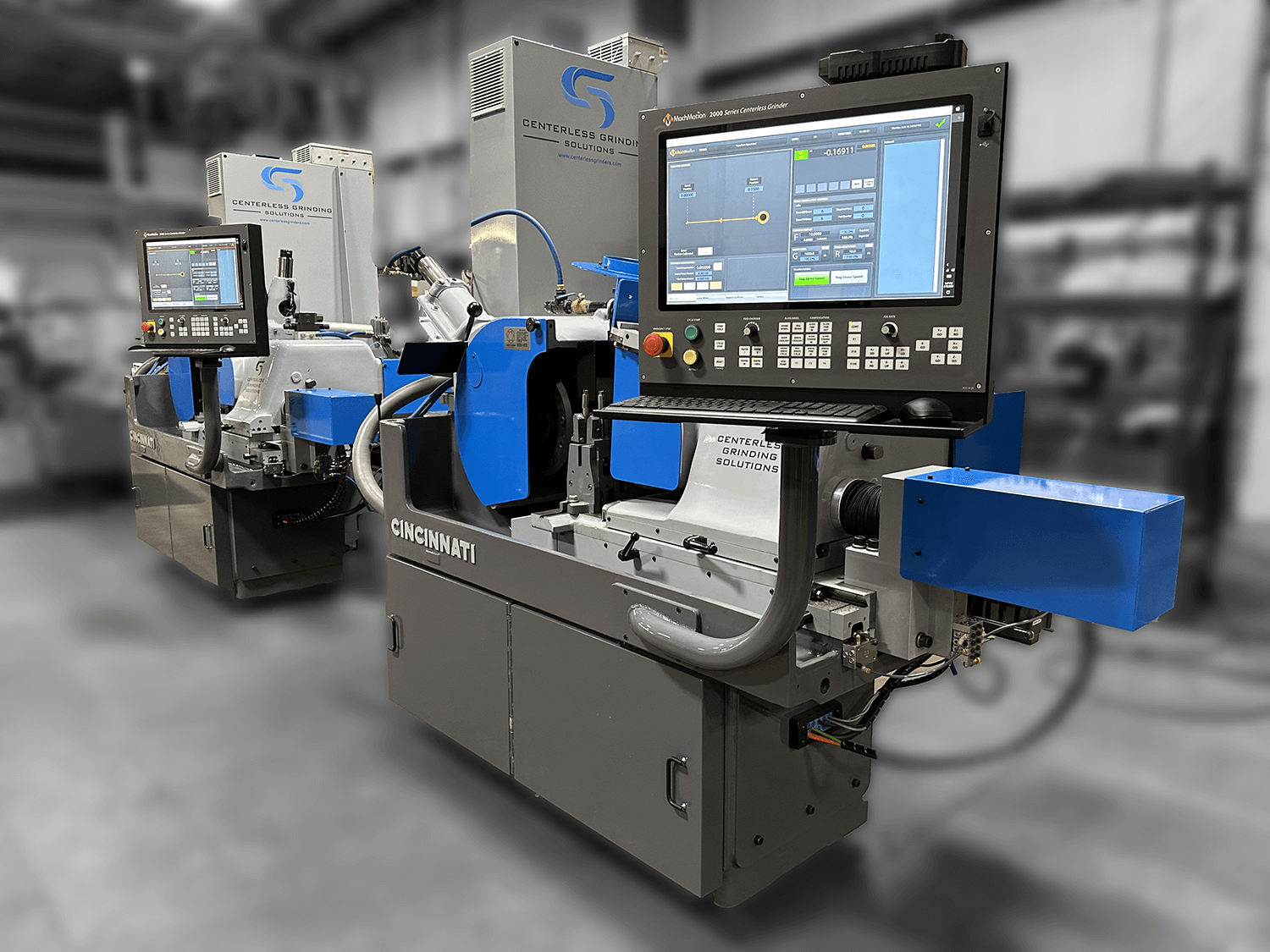

These upgrades transform older Cincinnati, Landis RK, and Landis Viking grinders into modern, precise machines that meet today’s tolerance requirements.

Addressing Shop Challenges

A CNC control retrofit specifically addresses the challenges manufacturers face:

Consistency: Modern CNC controls eliminate variability between operators, ensuring each part meets the same exacting standards regardless of who’s running the machine.

Precision: Servo-controlled regulating wheels allow micron-level adjustments, making it possible to hold tolerances that were previously difficult or impossible with manual controls.

Ease of Operation: Touchscreen HMI systems make setup and adjustments more intuitive, reducing the learning curve for new operators and speeding up changeovers between jobs.

Equipment Longevity: Rather than replacing functional machines, control upgrades breathe new life into proven equipment, extending its productive lifespan by decades.

Real-World Impact

Consider a job shop that retrofitted their Cincinnati centerless grinder with modern CNC controls and servo systems. They reported:

- Improved ability to hold tight tolerances consistently

- Reduced setup time between different part runs

- Greater confidence in taking on precision work

- Extended productive life of their existing equipment

These improvements showcase how control modernization enables smaller shops to compete on quality and precision without the capital investment of new machinery.

As we explore the specific benefits and applications of control upgrades, it becomes clear that modernization isn’t just an option—it’s a practical path forward for job shops looking to remain competitive with existing equipment.

looking to stay competitive in an increasingly demanding market.

Benefits of Control System Upgrades

Upgrading control systems on existing centerless grinders brings tangible advantages that resonate with job shops and manufacturers. Let’s explore these key benefits:

1. Improved Precision and Consistency

Modern control systems dramatically enhance grinding accuracy:

- Repeatable Results: CNC controls ensure consistent part quality across production runs

- Tighter Tolerances: Servo-driven regulating wheels enable precision that manual systems can’t match

- Reduced Variability: Digital controls eliminate the inconsistencies inherent in manual adjustments

2. Easier Operation and Setup

Modern interfaces make centerless grinding more accessible:

- Intuitive Touchscreens: HMI displays simplify machine operation and reduce training time

- Faster Changeovers: Digital settings can be saved and recalled, speeding up switches between different parts

- Better Diagnostics: Modern controls provide clear feedback, making troubleshooting easier

3. Extended Equipment Life

Control upgrades maximize your existing investment:

- Modernized Capability: Transform older machines to meet current precision requirements

- Continued Productivity: Keep proven equipment running rather than replacing it

- Cost-Effective Solution: Achieve modern performance at a fraction of new machine costs

4. Enhanced Competitive Position

Control modernization helps smaller shops compete effectively:

- Quality Confidence: Meet tighter specifications that customers increasingly demand

- Expanded Capabilities: Take on precision work previously outside your range

- Improved Efficiency: Reduce scrap and rework with more consistent results

5. Practical Implementation

Unlike full automation, control upgrades are manageable projects:

- Targeted Investment: Upgrade specific systems based on your needs and budget

- Minimal Disruption: Retrofits can often be completed during scheduled downtime

- Proven Technology: Modern CNC and servo systems are reliable and well-supported

By implementing these upgrades, job shops can significantly improve their grinding operations while working within realistic budgets and maintaining their existing equipment base.

Applications Across Industries

Control system upgrades benefit centerless grinding operations across diverse manufacturing sectors:

Automotive & Aerospace: Job shops producing precision shafts, pins, and components benefit from servo-controlled regulating wheels that maintain tight tolerances across production runs. The ability to save and recall exact grinding parameters ensures consistent results for critical applications.

Medical Device Manufacturing: Medical implants and surgical instruments require microscopic precision. Modern control systems enable job shops to achieve and maintain the exacting tolerances medical manufacturing demands, opening opportunities in this growing sector.

Industrial Tooling & Precision Components: Manufacturers of cutting tools, drill bits, and precision parts rely on centerless grinding for consistent results. A CNC control retrofit enables shops to handle tighter specifications while maintaining efficient production across various materials.

At Centerless Grinding Solutions, we specialize in modernizing Cincinnati, Landis RK, and Landis Viking centerless grinders. Our expertise in CNC control retrofits, servo system upgrades, and HMI touchscreen modernization helps job shops across industries update their existing equipment to meet current precision requirements. By focusing on targeted control system upgrades rather than full automation, we help shops improve precision and efficiency while maximizing their existing equipment investment.

Conclusion

Control system modernization is transforming how job shops approach centerless grinding. CNC control retrofits, servo system upgrades, and HMI touchscreen improvements deliver enhanced precision, improved consistency, and easier operation—without requiring full machine replacement.

For smaller manufacturers, these targeted upgrades provide a practical path to meeting today’s tighter tolerances and quality demands. By modernizing existing equipment, shops can extend the productive life of proven machines while gaining the precision capabilities needed to remain competitive.

The modernization journey begins with understanding your specific needs and working with experienced partners who specialize in centerless grinding control systems.

Ready to modernize your grinding operations? Contact Centerless Grinding Solutions today to explore how CNC control retrofits, servo upgrades, and touchscreen modernization can transform your existing centerless grinders and unlock new levels of precision and consistency.