CNC Centerless Grinding: The Complete Guide to Precision and Efficiency

CNC centerless grinding represents a revolutionary approach to precision manufacturing, delivering unmatched accuracy and production efficiency for cylindrical components. This advanced machining process combines computer numerical control with centerless grinding technology to produce parts with tolerances as tight as 0.0001 inches while dramatically reducing setup times and labor costs.

Whether you’re manufacturing medical devices, automotive components, or aerospace parts, understanding cnc centerless grinding capabilities can transform your production operations and competitive positioning in today’s demanding manufacturing landscape.

What Is CNC Centerless Grinding?

CNC centerless grinding is an automated precision machining process that removes material from cylindrical workpieces without using traditional centers or chucks to hold the part. Instead, the workpiece is supported between a grinding wheel, a regulating wheel, and a workrest blade, allowing continuous feeding and processing of parts with exceptional consistency.

Unlike conventional centerless grinding that relies on manual adjustments, cnc centerless grinding incorporates computer-controlled servo systems that precisely manage wheel positioning, feed rates, and grinding parameters. This automation delivers superior repeatability across production runs while minimizing operator intervention and human error.

The process excels at producing high-volume cylindrical components including pins, shafts, rollers, and medical guidewires with diameter tolerances measured in tenths of thousandths of an inch. Modern CNC systems can automatically adjust for wheel wear, compensate for temperature variations, and switch between different part programs without manual reconfiguration.

How CNC Centerless Grinding Works

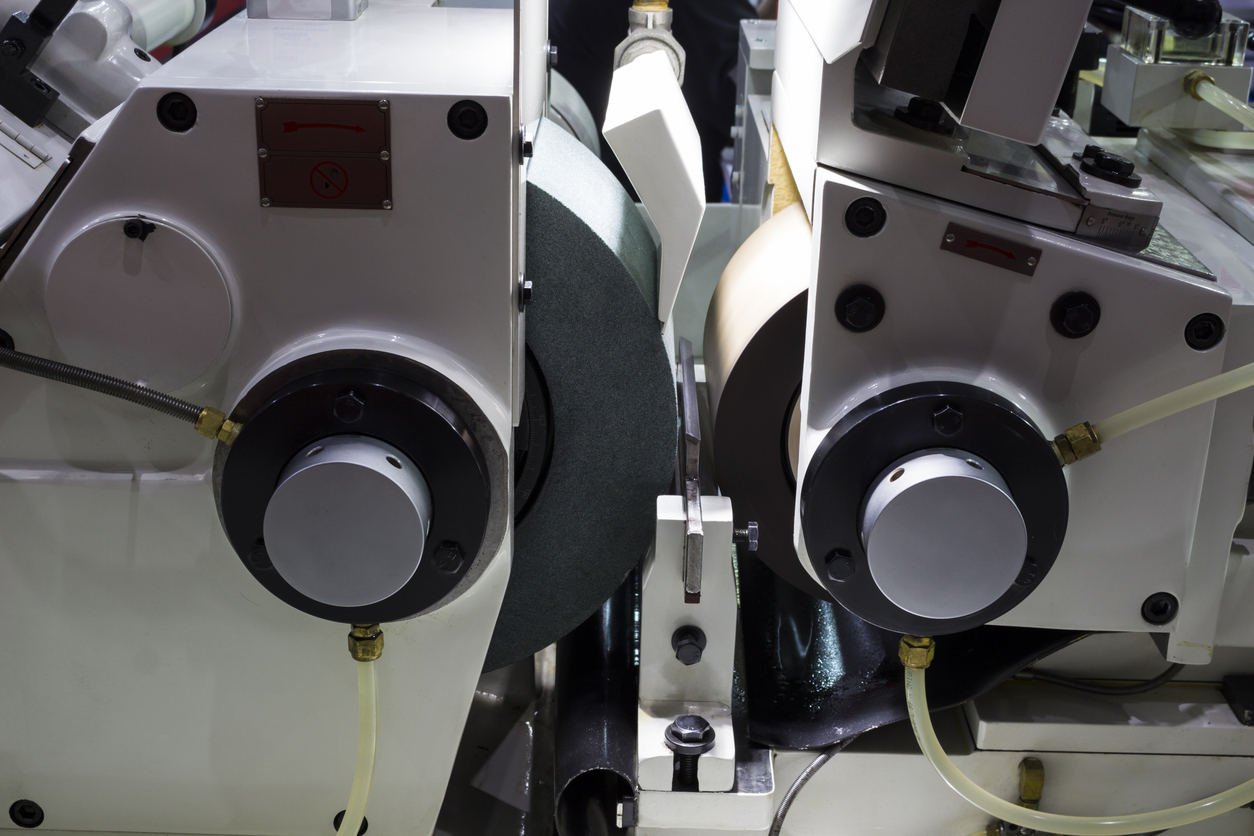

The fundamental mechanics of cnc centerless grinding involve three critical components working in synchronized harmony. The grinding wheel rotates at high speed to remove material from the workpiece surface. The regulating wheel, positioned opposite the grinding wheel, rotates more slowly to control the workpiece rotation and feed rate through the grinding zone.

Between these two wheels sits the workrest blade, which supports the workpiece at a precise height and angle. The CNC system continuously monitors and adjusts the position of the regulating wheel, modifying the grinding pressure and feed rate based on programmed parameters and real-time sensor feedback.

In through-feed grinding, parts move continuously between the wheels from one side to the other, making it ideal for high-volume production of parts with consistent diameters. In-feed grinding positions the workpiece against the wheels while the regulating wheel moves inward to achieve the final diameter, perfect for components with shoulders, tapers, or complex profiles.

The CNC controller manages all critical variables including wheel speeds, regulating wheel angle, workrest blade position, coolant flow, and dwell times. Operators input part specifications through intuitive interfaces, and the system automatically calculates optimal grinding parameters for each component geometry.

Key Advantages of CNC Centerless Grinding

Unparalleled Precision and Consistency

CNC centerless grinding routinely achieves tolerances of ±0.0001 inches with surface finishes ranging from 8 to 32 micro-inches Ra. The elimination of manual adjustments removes operator variability, ensuring every part meets identical specifications regardless of production volume. Advanced servo control maintains consistent grinding pressure throughout the process, compensating for wheel wear and thermal expansion.

For industries like medical device manufacturing and aerospace, where component failures can have catastrophic consequences, this level of precision reliability is non-negotiable. CNC systems document every grinding parameter for complete traceability and quality assurance compliance.

Exceptional Production Efficiency

Through-feed cnc centerless grinding can process hundreds or thousands of parts per hour with minimal operator attention. The continuous feeding mechanism eliminates the loading and unloading cycles required by conventional grinding methods, dramatically reducing cycle times for simple cylindrical components.

Automated wheel dressing cycles maintain optimal grinding performance without production interruptions. Quick-change tooling and stored CNC programs enable rapid changeovers between different part numbers, reducing setup times from hours to minutes. This flexibility makes CNC centerless grinding economically viable for both high-volume production runs and smaller specialty batches.

Reduced Labor Requirements

Traditional centerless grinding demands skilled operators who understand the complex relationships between wheel positions, feed rates, and grinding results. CNC automation distills this expertise into programmed parameters, allowing less experienced operators to produce expert-level results consistently. A single operator can often supervise multiple CNC grinding machines simultaneously, optimizing labor utilization.

The reduction in manual wheel dressing, measurement, and adjustment tasks decreases operator fatigue and increases throughput. Emergency stop systems and automated error detection protect both equipment and operators while maintaining production flow.

Cost-Effective Solutions for Various Production Volumes

While CNC centerless grinding equipment represents a significant capital investment, the operational savings quickly justify the expense for many applications. Reduced scrap rates, decreased rework, and improved first-pass yield rates directly impact profitability. Lower labor costs per part and increased throughput accelerate return on investment.

For manufacturers with existing conventional centerless grinders, CNC retrofits offer a cost-effective path to automation without replacing entire machines. Modern servo systems and controllers can transform manual equipment into precision CNC operations at a fraction of new equipment costs.

Selecting the Right Solution

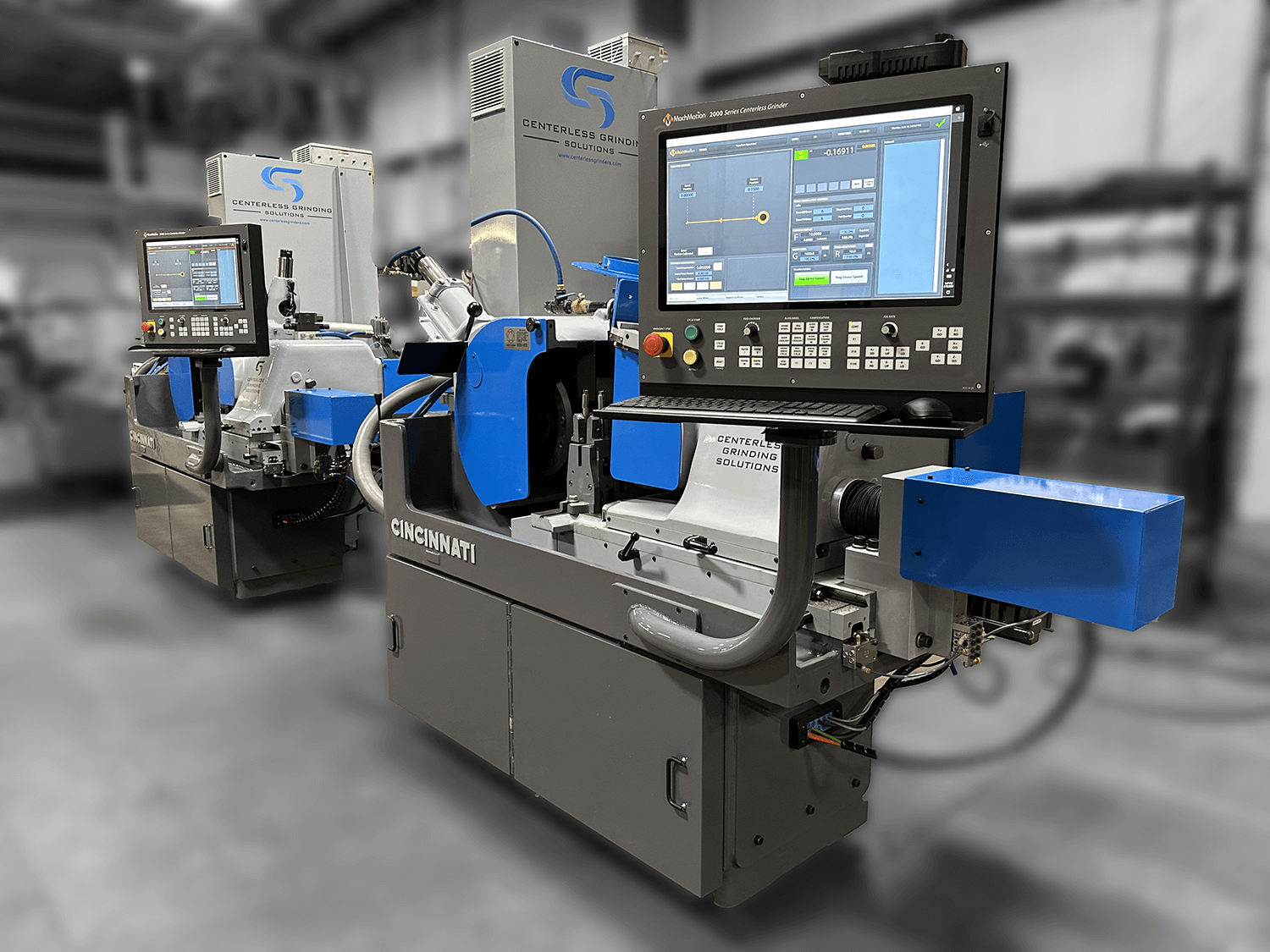

Choosing between new CNC equipment and retrofitting existing machinery depends on your specific production requirements, budget constraints, and timeline. New CNC centerless grinders offer the latest technology, comprehensive warranties, and turnkey installation, but require substantial capital investment ranging from $500,000 to over $1,000,000.

CNC retrofits provide a cost-effective alternative, transforming reliable conventional equipment into precision automated systems for 30-70% less than new machine costs. Retrofits preserve your investment in existing infrastructure while dramatically improving capabilities. The decision depends on factors including machine condition, available space, production volume requirements, and strategic manufacturing plans.

For manufacturers with Cincinnati or Landis centerless grinders, specialized remanufacturing services combine complete mechanical rebuilding with state-of-the-art CNC control integration. These comprehensive overhauls essentially create “new” machines at a fraction of replacement costs, backed by warranties comparable to new equipment.

Maintenance and Optimization Best Practices

Maximizing the performance and longevity of cnc centerless grinding equipment requires disciplined preventative maintenance and continuous optimization. Daily inspection routines should verify coolant concentration, wheel condition, and hydraulic fluid levels. Regular wheel dressing maintains consistent grinding geometry and surface finish characteristics.

CNC systems benefit from periodic calibration to ensure servo accuracy remains within specifications. Monitoring error logs and alarm histories helps identify developing issues before they cause production disruptions. Many modern CNC controllers offer predictive maintenance alerts based on operating hours and cycle counts.

Proper training ensures operators understand both the mechanical grinding process and CNC programming fundamentals. Cross-training maintenance personnel on both mechanical systems and control electronics reduces downtime when issues arise. Establishing relationships with experienced service providers who specialize in your equipment brand provides valuable support resources.

The Future of CNC Centerless Grinding

The evolution of CNC centerless grinding continues accelerating as Industry 4.0 technologies integrate with precision machining processes. IoT-enabled monitoring systems now provide real-time performance data, enabling remote diagnostics and predictive maintenance scheduling. Cloud-based analytics identify optimization opportunities across entire manufacturing operations.

Sustainability considerations are driving innovations in coolant management, energy efficiency, and waste reduction. Modern CNC systems optimize grinding parameters to minimize wheel consumption and extend component life while maintaining precision requirements.

As manufacturing continues reshoring to North America and skilled labor shortages persist, the role of CNC automation in maintaining competitive precision manufacturing capabilities will only increase. Investing in advanced cnc centerless grinding technology positions manufacturers to meet both current production demands and future market opportunities.

Take the Next Step in Precision Manufacturing

CNC centerless grinding represents the intersection of mechanical precision and digital control, delivering manufacturing capabilities that were impossible just decades ago. Whether you’re considering new equipment, exploring retrofit options, or seeking to optimize existing operations, understanding these advanced technologies is essential for competitive precision manufacturing.

The key to success lies in partnering with experienced providers who understand both the mechanical intricacies of centerless grinding and the complexities of CNC integration. Look for specialists who offer comprehensive solutions including equipment, training, parts support, and ongoing technical assistance to ensure your investment delivers long-term value.

Ready to upgrade your grinding capabilities? Centerless Grinding Solutions brings over 35 years of expertise in CNC retrofits, remanufacturing, and comprehensive grinding services for Cincinnati and Landis equipment. Contact our team today to discuss how we can enhance your precision manufacturing operations with cost-effective CNC solutions tailored to your specific needs.