Centerless Wheel Balancing: 4 Signs You Need an Automatic System

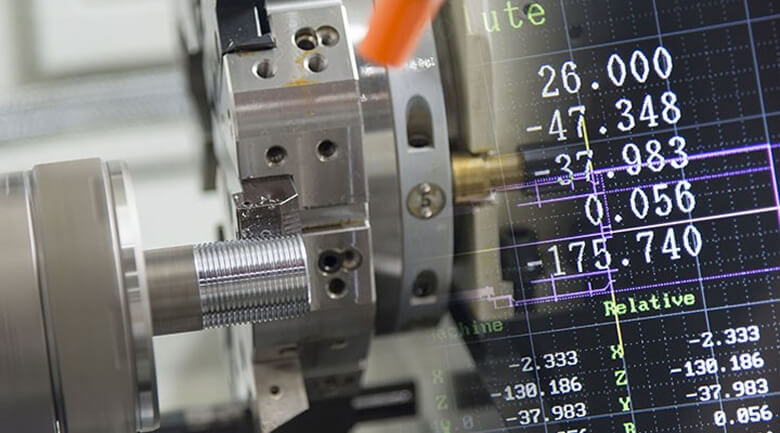

You know something’s wrong when your centerless grinder starts producing inconsistent parts.

The surface finish looks rough. Dimensional accuracy drifts. Your maintenance team spends more time troubleshooting than they should.

The root cause? An unbalanced grinding wheel.

Most shops discover they need a dedicated centerless wheel balancing system after they’ve already paid the price in downtime, scrapped parts, and frustrated operators. This guide helps you recognize the signs before those costs pile up.

The Real Cost of Ignoring Wheel Balance

Unplanned downtime costs manufacturers up to $260,000 per hour according to IIoT World research. The average manufacturer faces 800 hours of unplanned downtime per year—that’s roughly 15 hours every week paying employees to wait while machines sit idle.

When your grinding wheel loses balance, you’re not just dealing with vibration. You’re facing:

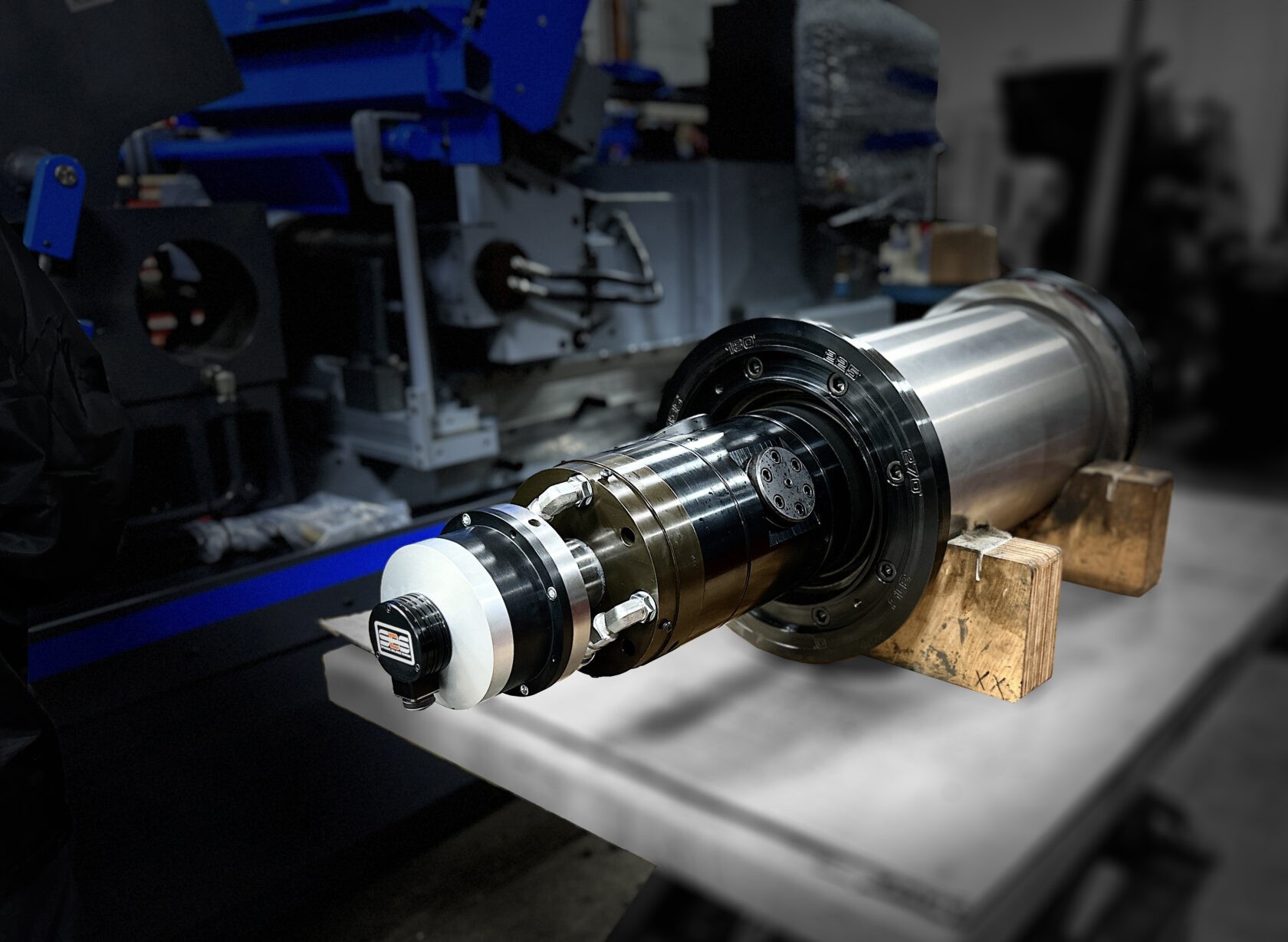

Premature spindle bearing failure. The constant stress from an unbalanced wheel shortens bearing life and leads to early spindle replacement—one of your most expensive maintenance items.

Surface finish defects. Chatter marks, circularity errors, and faceting appear on your workpieces. Parts that should pass inspection get scrapped or require rework.

Reduced metal removal rates. Your production slows down because operators compensate for vibration by reducing feed rates and grinding speeds.

These problems compound quickly. What starts as a minor vibration becomes a production bottleneck that affects your entire operation.

4 Signs You Need an Automatic Balancing System

1. Your Traditional Methods Take Too Long

Stroboscopic balancing and manual balancing stands require specialist knowledge and eat up valuable production time. Your operators spend 30 minutes or more balancing a single wheel—time that could be spent grinding parts. An automatic SBS System eliminates this bottleneck by balancing wheels in minutes with minimal operator intervention.

Worse, when you balance outside the grinding machine, you miss residual unbalance in the spindle bearing and clamping errors. The wheel might seem balanced on the stand, but it still vibrates once mounted.

2. You’re Running Modern, High-Speed Grinders

As grinding technology advances with higher RPMs and tighter tolerances, wheel balance becomes more important. An imbalance that was acceptable at 3,000 RPM becomes destructive at 5,000 RPM. This is where an SBS System proves essential for maintaining precision at higher speeds.

Modern grinders demand precise balancing. The superior surface finishes they’re capable of achieving only happen when vibration is virtually eliminated.

3. Your Wheels Wear Down During Processing

Here’s the challenge: wheel diameter reduces continuously during grinding. That means the unbalance changes throughout the shift.

Without a balancing system that allows for quick, frequent rebalancing, you’re constantly chasing vibration issues. Your operators know the parts ground at the start of the wheel’s life look different from those ground near the end.

4. You’re Losing Money on Productivity

Balancing wheels and tools boosts metal removal rates. On a single-shift operation with a machine rate of just $115 per hour, that productivity gain pays for balancing equipment within a year.

You’re leaving money on the table every shift you run without proper balancing.

What a Proper Balancing System Delivers

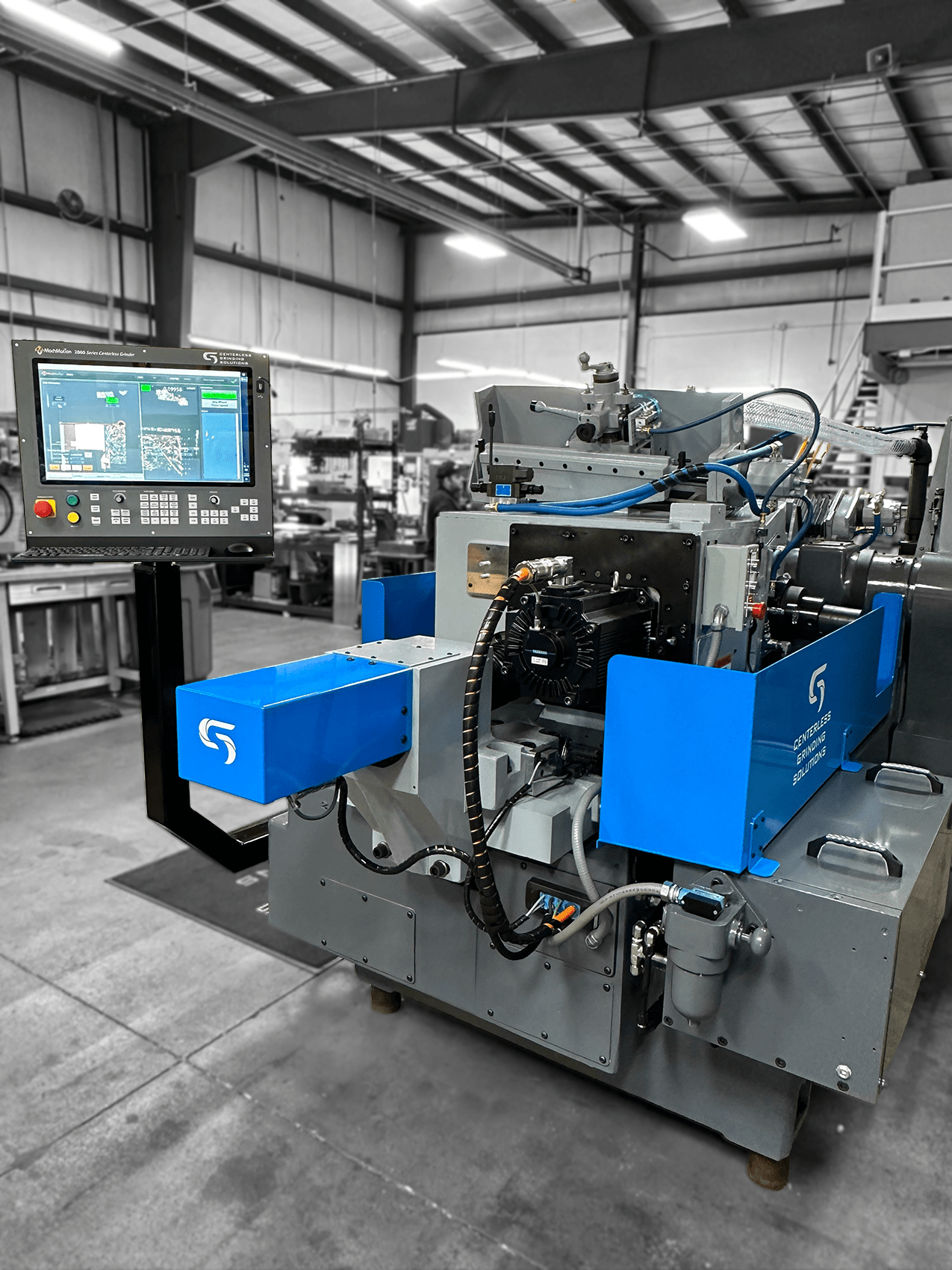

A dedicated centerless wheel balancing system—like an SBS System—transforms how your shop operates.

Reduced setup time. Balance wheels in minutes instead of half an hour. Your operators spend more time producing parts and less time fighting vibration.

Extended spindle life. By stabilizing the machine and eliminating vibration, you dramatically reduce stress on spindle bearings. The ideal condition for production continuity.

Consistent part quality. When your grinding and regulating wheels maintain proper balance, you achieve the accuracy and surface finish your customers expect. No more chatter marks or dimensional drift.

Safer operation. Unbalanced wheels create serious safety risks for personnel and equipment. Proper balancing protects your team and your investment.

Making the Decision

Ask yourself these questions:

Are you experiencing frequent spindle bearing failures? Do your operators complain about vibration? Are you seeing surface finish defects that shouldn’t be there?

Is your maintenance team spending too much time on centerless wheel balancing? Are you running high-speed grinders that demand tighter tolerances?

If you answered yes to any of these, you need a balancing system.

The shops that invest in proper wheel balancing see immediate gains in uptime, part quality, and overall equipment effectiveness. The shops that delay the decision keep paying for it in downtime and scrapped parts.

Your Next Step

At Centerless Grinding Solutions, we help shops like yours identify the right balancing solution for your specific needs. With over 30 years of experience in centerless grinding, we understand the challenges you face.

We’ll work with you to assess your current setup, identify improvement opportunities, and recommend equipment that delivers measurable results. Our focus is on minimizing your downtime and maximizing your production efficiency.

Ready to eliminate vibration issues and improve part quality? Contact our team to discuss your balancing needs. We’re here to help you keep your operations running smoothly.