Our modern equipment upgrades and technology integration can transform your operations into a competitive powerhouse. Whether you seek enhanced precision, increased efficiency, or streamlined processes, our upgrade solutions are designed to drive long-term success.

Looking To Modernize Your Centerless Grinders?

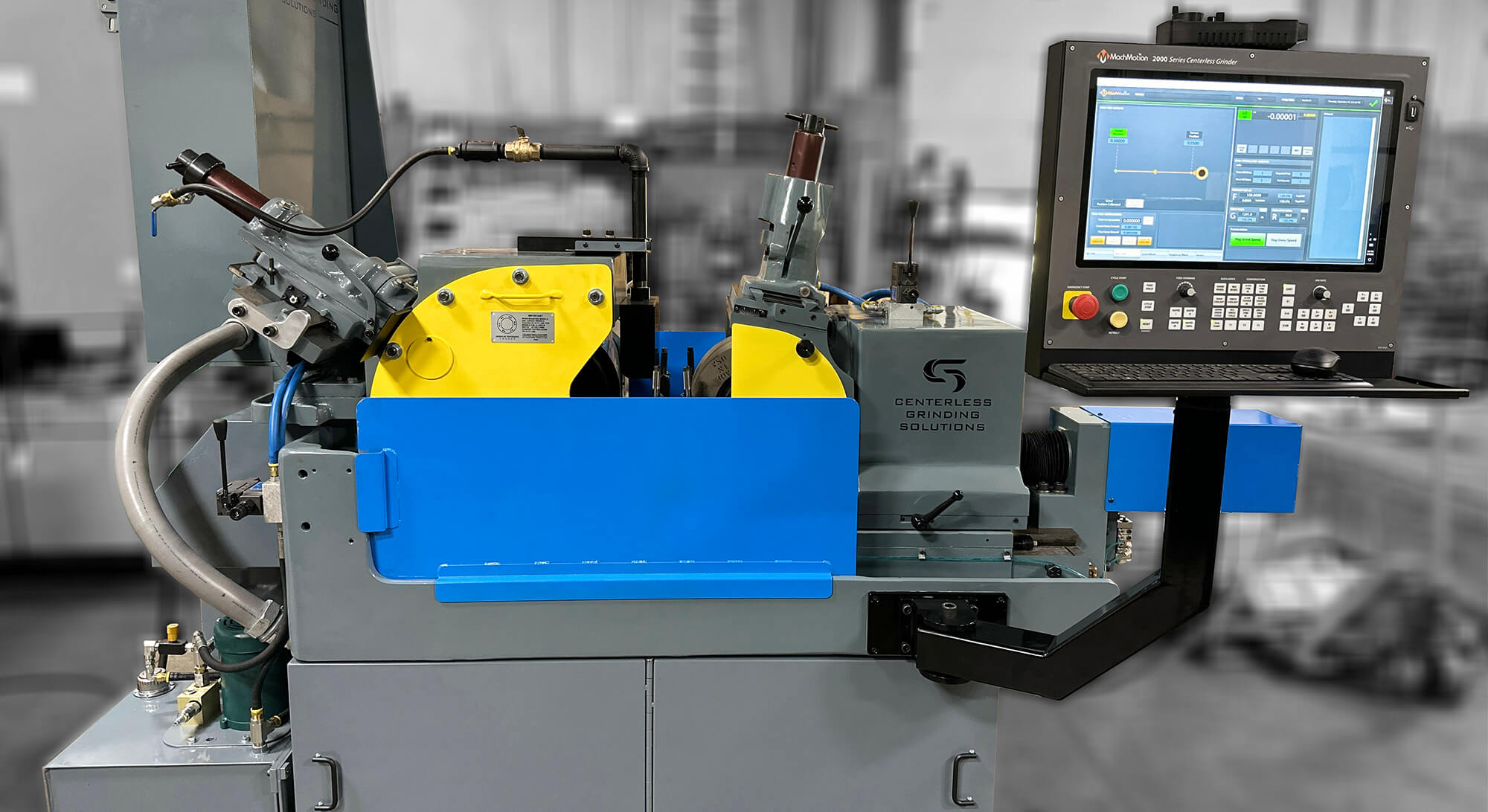

Choose Your Next Centerless Grinding Machine Upgrade & Retrofit

Centerless Grinder Control Retrofit

Modernize your grinder with our advanced control system: touchscreen, wireless operation, and remote access for superior precision.

Regulating Wheel Servo Upgrade

Upgrade your grinder's regulating wheel with our servo conversion kits for improved precision and reduced maintenance, a smart investment for long-term savings.

Need Specialized Equipment Training?

Maximize the use of new technology is a top priority. We’re here to support you in modernizing your centerless grinding machines and bridging the skills gap within your workforce, in the most cost-effective way. We offer specialized centerless grinding training and ongoing support to ensure a smooth transition for your team and yourself.

Let's Work Together

We are dedicated to delivering cost-effective centerless grinding solutions that reduce downtime, boost efficiency, and achieve the finest quality in precision grinding. Ready to discuss your specific requirements or need more details? Contact us today. Our experts are always ready to assist you.