Centerless Grinder Automation: Unleashing New Efficiencies in Manufacturing

Centerless grinder automation has moved beyond loading robots and basic mechanization.

Today’s centerless grinder automation systems integrate CNC controls, robotic handling, and real-time process monitoring to deliver precision that manual operations can’t match. The technology transforms how manufacturers approach cylindrical part production, eliminating bottlenecks while improving quality metrics across the board.

Understanding centerless grinder automation helps you make informed decisions about which systems deliver measurable returns for your specific operations.

CNC Systems Redefine Precision Control

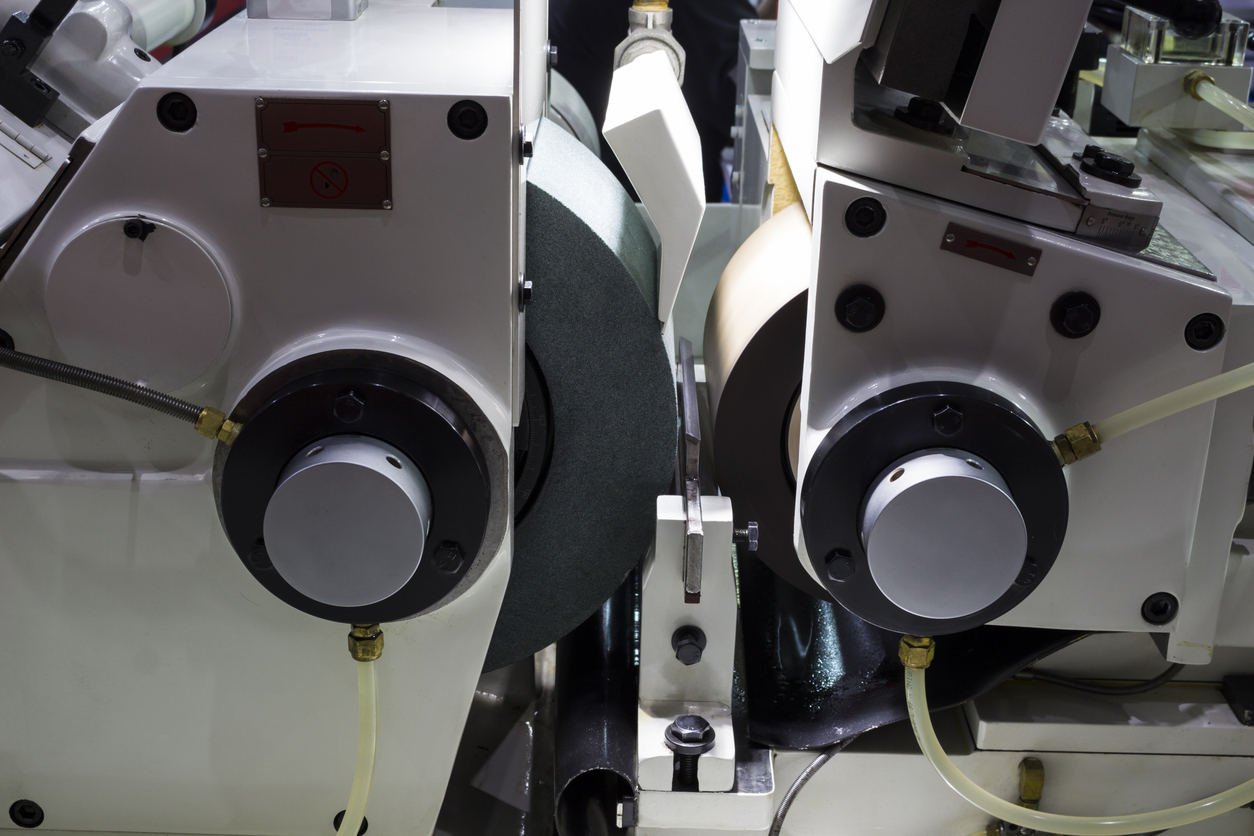

Centerless grinder automation with modern CNC systems uses closed-loop feedback systems that continuously adjust grinding parameters based on real-time measurements. Feed rates, wheel speeds, and work rest blade positioning respond dynamically to variations in workpiece dimensions or material hardness.

The control systems monitor dozens of variables simultaneously. Grinding wheel wear, coolant temperature, part diameter, and surface finish all feed into algorithms that optimize the process without operator intervention.

This level of precision control reduces scrap rates dramatically. Where manual operations might see 3-5% defect rates due to operator variation, CNC-automated systems consistently achieve sub-1% defect rates once properly calibrated.

The programming flexibility matters too. You can store multiple grinding programs and switch between part specifications in minutes rather than hours. Setup time drops from the hours required for manual wheel dressing and positioning to the minutes needed for program selection and workpiece loading.

Robotic Integration Handles the Heavy Lifting

Robotic loading and unloading systems eliminate the physical demands and safety risks of manual part handling. Collaborative robots work alongside grinding equipment, managing workpiece flow from raw material bins through the grinding cycle to finished part collection.

The robots don’t just move parts. They orient them precisely, ensuring consistent positioning that directly impacts grinding accuracy. Vision systems verify part dimensions before grinding begins, rejecting out-of-spec blanks before they consume machine time.

Integration with conveyor systems and automated storage creates continuous flow manufacturing. Parts move through multiple grinding operations without human touch, reducing handling damage and contamination while enabling true lights-out operation.

The labor shortage affecting 800,000 manufacturing positions makes this capability increasingly critical. Automated cells run second and third shifts without staffing concerns.

The ROI Calculation Gets Simpler

Automation delivers returns through multiple channels that compound over time.

Labor cost reduction represents the most visible benefit. A single automated cell can replace 2-3 operator positions across multiple shifts. But the deeper value comes from consistency and throughput improvements.

Many manufacturers report payback within two years, factoring in the 22% reduction in operating costs that centerless grinder automation typically delivers. That includes reduced scrap, lower energy consumption per part, and decreased maintenance costs from optimized grinding parameters.

The centerless grinding market growth from $6.9 billion in 2024 to a projected $15.4 billion by 2032 reflects manufacturers recognizing these economics. Industry 4.0 integration and IoT-enabled equipment drive much of that expansion.

Throughput gains often surprise plant managers. Automated systems process workpieces 20-30% faster than manual operations because loading and unloading happen in optimized cycles without variation. The grinding process itself runs at peak efficiency continuously rather than degrading as operators fatigue.

Retrofitting Existing Equipment Makes Sense

You don’t need to replace functional grinders to gain automation benefits.

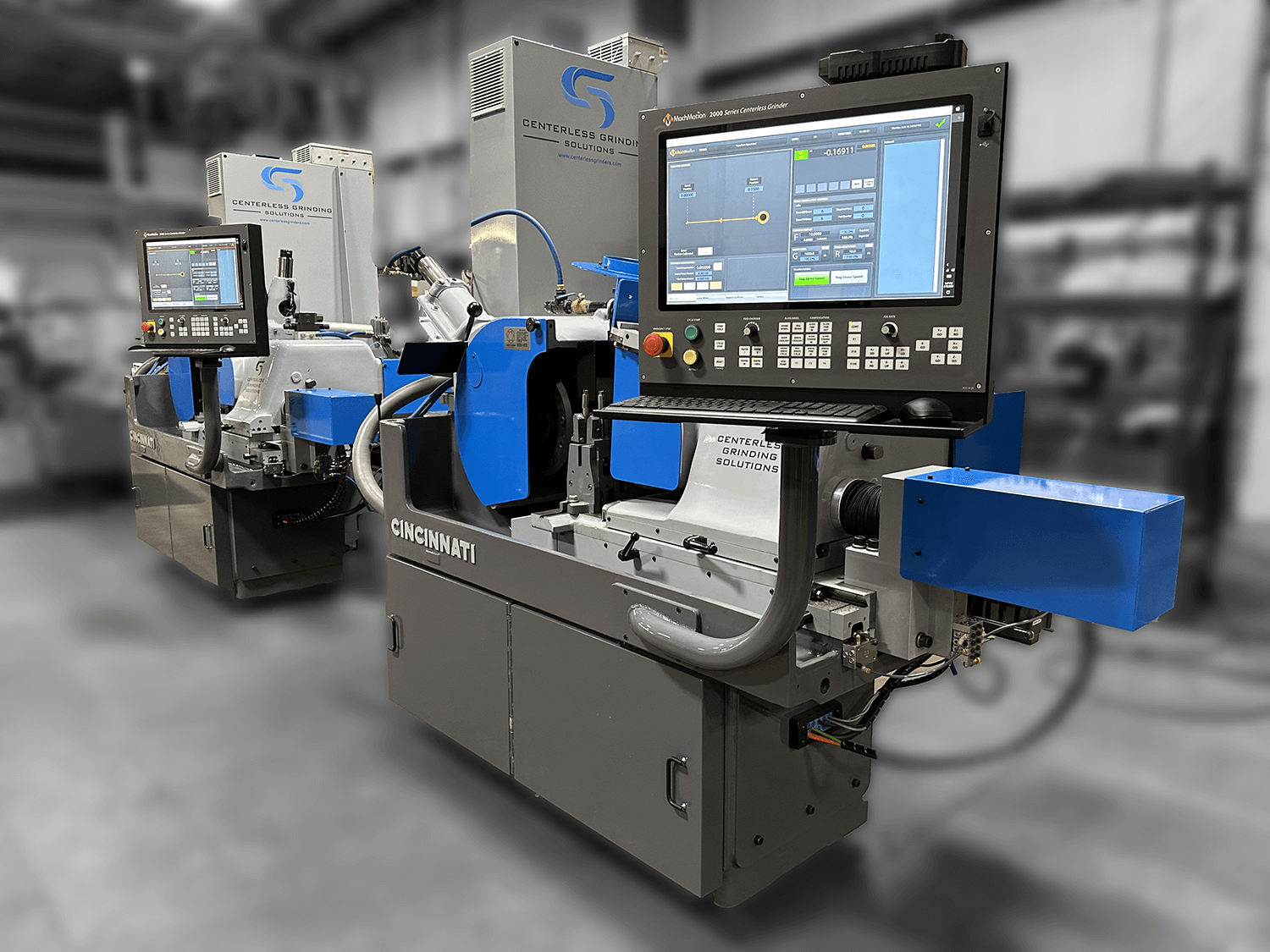

Centerless grinder automation through rebuilding upgrades existing machines with modern CNC controls, servo drives, and robotic interfaces. The mechanical foundation gets restored to like-new condition while the control systems bring current-generation capabilities.

This approach cuts capital costs by 40-60% compared to new automated grinders while eliminating the 12-18 month lead times common for new equipment orders. You maintain familiarity with proven machine configurations while gaining the precision and throughput of modern automation.

The rebuild process integrates sensors for predictive maintenance, connectivity for remote monitoring, and control interfaces that match current industry standards. Your operators work with familiar equipment that now delivers automated performance.

Implementation Requires Planning

Successful automation projects start with process analysis. Which operations create bottlenecks? Where do quality issues originate? What throughput gains would impact your bottom line most significantly?

The answers guide centerless grinder automation system design. A high-mix, low-volume operation needs different automation than a dedicated line producing millions of identical parts annually. Flexibility requirements, changeover frequency, and quality specifications all influence the optimal configuration.

Integration with existing manufacturing execution systems matters. Automated grinders generate data on cycle times, tool wear, quality metrics, and maintenance needs. That information feeds production planning, inventory management, and continuous improvement initiatives when properly connected to your broader systems.

Training your team ensures you extract full value from automation investments. Operators become system supervisors, monitoring multiple machines and responding to exceptions rather than manually loading parts. Maintenance staff learn to service robotic systems and troubleshoot CNC controls alongside traditional mechanical components.

Centerless Grinder Automation Technology Keeps Advancing

Centerless grinder automation capabilities continue expanding. Machine learning algorithms now optimize grinding parameters based on accumulated process data. Predictive maintenance systems forecast component failures before they cause downtime. Digital twins simulate process changes before implementing them on the shop floor.

These advances make automation increasingly accessible to mid-sized manufacturers who previously couldn’t justify the investment. Modular systems allow incremental automation, starting with basic robotic loading and adding capabilities as ROI proves out.

The manufacturers implementing automation today build expertise that becomes a competitive advantage. They optimize processes, train skilled staff, and establish the operational patterns that maximize return on their automation investments.

Your grinding operations can deliver higher precision, better consistency, and improved throughput. The technology exists, the economics work, and the implementation pathways are proven.

The question is whether you’ll automate while it’s still a competitive advantage or wait until it becomes a competitive necessity.

Ready to explore the potential of centerless grinder automation or elevate your current operations? Contact Centerless Grinding Solutions for personalized advice, training, and support. Start transforming your grinding operations into a beacon of efficiency and precision today.