Best Practices for Maintaining Centerless Grinding Machines

Key Takeaways

- Proactive maintenance programs deliver measurable ROI through extended equipment lifespan, consistent part quality, and predictable operating costs

- A systematic approach with daily, weekly, monthly, and quarterly maintenance intervals prevents small issues from becoming expensive production stoppages

- Early warning signs like increased vibration, declining part quality, and unusual noises indicate immediate attention is needed to avoid catastrophic failure

- Documented maintenance records, trained operators, and partnerships with specialized service providers create programs that actually work long-term

Equipment failure is the leading cause of unplanned production stoppages, but it doesn’t have to be. A systematic maintenance approach transforms unpredictable breakdowns into manageable, scheduled service windows.

This guide walks you through proven maintenance practices that extend equipment life, maintain precision tolerances, and protect your operators—all while keeping your production schedule intact.

Why Grinding Machine Maintenance Delivers Measurable ROI

A proactive maintenance program does more than just keep machines running. It delivers measurable returns across your entire operation, from equipment longevity to operator safety to consistent part quality.

Here’s what proper maintenance delivers:

Extended equipment lifespan. Your centerless grinding machines represent a significant capital investment. Regular maintenance minimizes cumulative wear and tear, ensuring your equipment maintains precision and accuracy for years beyond typical expectations.

Consistent part quality. Properly maintained machines deliver the tight tolerances and surface finishes your customers expect. You avoid the costly cycle of rework, scrap, and damaged customer relationships that come from inconsistent grinding results.

Improved operator safety. Manufacturing accounts for 15% of all workplace injuries despite employing only 8% of workers. Safety experts emphasize that the vast majority of these injuries are preventable through proper equipment maintenance, comprehensive training, and vigilant safety measures.

Predictable operating costs. When you shift from reactive repairs to planned maintenance, you gain control over your budget. You schedule maintenance during planned downtime, order parts in advance, and avoid the premium costs of emergency service calls.

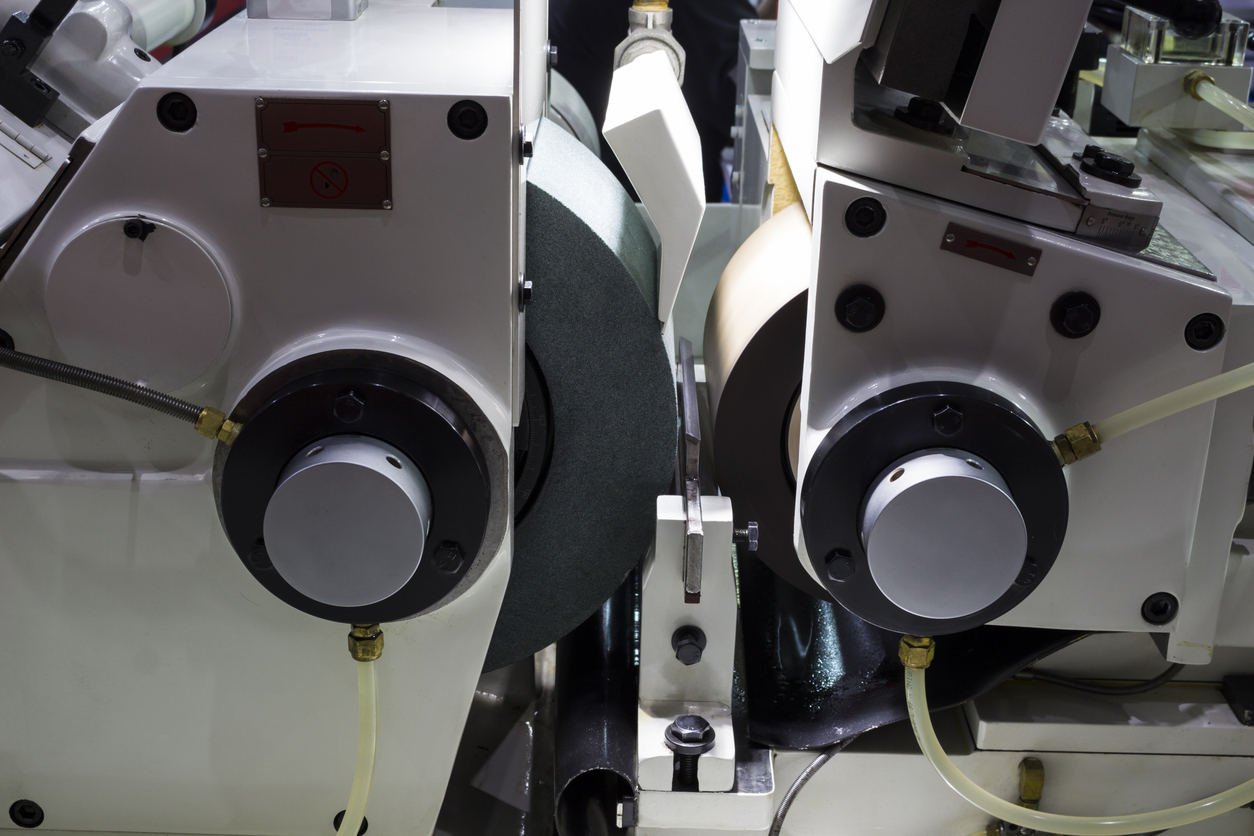

Your Complete Grinding Machine Maintenance Checklist

A systematic approach to grinding machine maintenance prevents small issues from becoming expensive problems. Break your maintenance tasks into daily, weekly, monthly, and quarterly intervals.

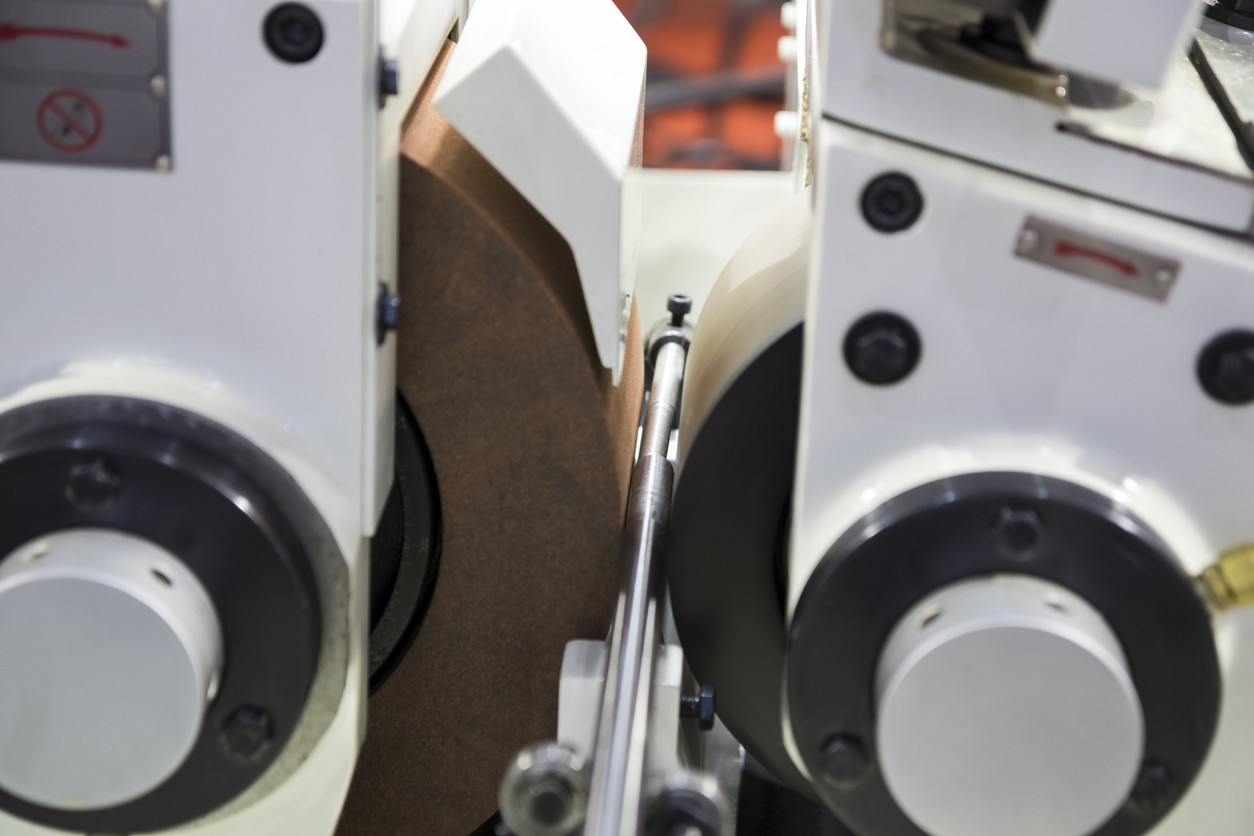

Daily Maintenance Tasks

Start each shift with a quick visual inspection. Look for leaks, loose components, or any signs of unusual wear. This takes five minutes but catches problems before they escalate.

Clean the machine and surrounding area. Remove debris and coolant buildup that can affect performance and create safety hazards.

Check coolant levels and quality. The coolant system plays a crucial role in preventing overheating and ensuring efficient debris removal. Overheating damages components, reduces machine lifespan, and causes defective production.

Verify machine alignment and settings. Confirm that your centerless grinder maintains proper setup for the day’s production requirements.

Weekly Maintenance Protocol

Lubricate bearings and moving parts according to manufacturer specifications. Proper lubricant levels are critical for spindle bearings, slides and guides, and ball screws. Regular lubrication ensures smooth operation and extends component life.

Monitor vibration levels and runout. Unusual vibrations signal potential bearing issues, spindle problems, or other mechanical concerns that need immediate attention.

Inspect grinding wheels for signs of wear, damage, or imbalance. Worn wheels compromise part quality and can create safety risks.

Monthly Deep Maintenance

Schedule time for thorough cleaning of the machine and coolant system. This prevents buildup and contamination that gradually degrade performance.

Inspect belts and filters. Replace worn components before they fail during production. Dirty components can reduce output or stop production entirely.

Tighten loose bolts and fasteners. Vibration during operation gradually loosens connections. Regular tightening maintains machine stability and precision.

Check rest blade alignment. Misalignment causes defective products and affects your ability to meet production goals.

Quarterly and Biannual Service

Conduct comprehensive performance testing of all machine functions and controls. Verify that your centerless grinder operates within specification.

Inspect electrical components for damage, deterioration, or loose connections. Electrical issues often develop gradually before causing sudden failures.

Examine hydraulic systems. Faults in hydraulic components affect machine reliability and can lead to unexpected downtime.

Schedule professional maintenance service with qualified technicians who understand the specific requirements of centerless grinding equipment. Expert service addresses complex issues and performs in-depth servicing that goes beyond routine maintenance.

Warning Signs Your Grinding Machine Needs Immediate Attention

Even with diligent maintenance, you need to recognize early warning signs of trouble.

Increased vibration or unusual noise indicates potential bearing failure, spindle issues, or other mechanical problems. These symptoms lead to reduced grinding accuracy and accelerated wear if left unaddressed.

Declining part quality or inconsistent results signal worn grinding wheels, misaligned components, or machine setting problems. When you notice precision dropping or surface finish variations, investigate immediately.

Difficulty maintaining coolant levels suggests leaks or blockages in the system. Inadequate cooling and lubrication damage grinding wheels and compromise part quality.

Unusual odors or overheating components indicate lubrication issues, coolant problems, or electrical concerns that require immediate attention to prevent further damage.

Visible fluid leaks around the machine create safety hazards and compromise performance. Whether coolant, oil, or other fluids, leaks demand prompt resolution.

Address these warning signs immediately. The cost of investigating a potential problem is minimal compared to the expense of catastrophic failure during production.

Building a Maintenance Program That Actually Works

The difference between a maintenance checklist and an effective maintenance program comes down to implementation.

Document everything. Keep detailed records of all maintenance activities, including dates, tasks completed, parts replaced, and any observations. This documentation helps you identify patterns, predict future needs, and demonstrate compliance with safety requirements.

Train your operators. The people running your centerless grinders every day are your first line of defense against problems. Teach them what normal operation looks and sounds like so they can spot issues early.

Stock critical spare parts. Identify the components most likely to need replacement and keep them in inventory. The cost of maintaining spare parts inventory is minimal compared to the cost of waiting days or weeks for emergency parts delivery.

Partner with experienced service providers. Complex maintenance tasks and major repairs require specialized expertise. Establish relationships with qualified technicians before you need emergency service.

Track maintenance metrics. Monitor key indicators like mean time between failures, maintenance costs as a percentage of asset value, and planned versus unplanned maintenance ratios. These metrics help you continuously improve your program.

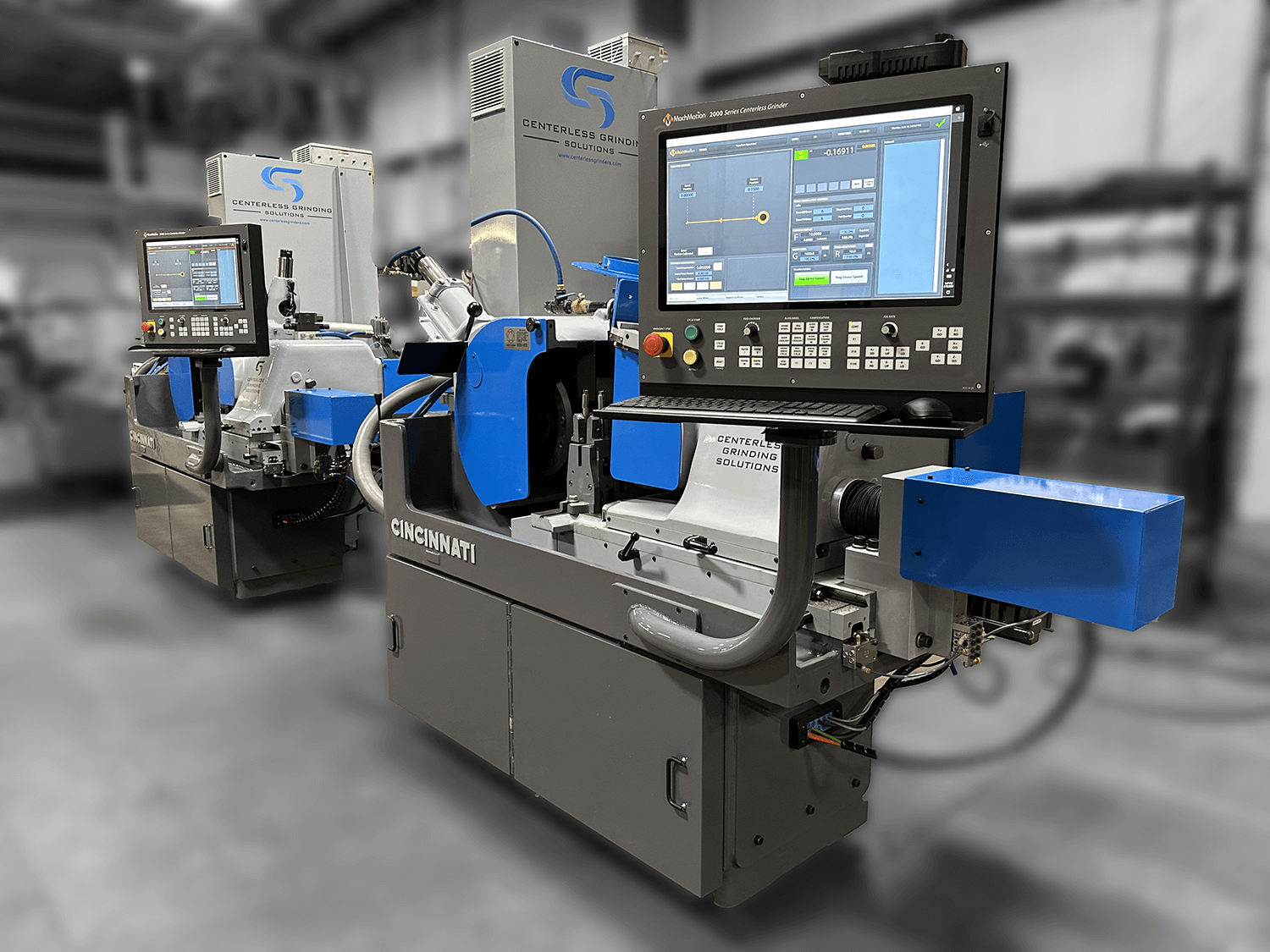

Partner With Grinding Machine Maintenance Experts

At Centerless Grinding Solutions, we’ve spent over 30 years helping manufacturers maximize the performance and lifespan of their centerless grinding equipment.

We understand that every operation faces unique challenges. Our team works with you to develop customized maintenance programs that fit your production schedule, budget constraints, and performance requirements.

From routine preventative maintenance to complex repairs and complete machine remanufacturing, we provide the expertise and support you need to keep your centerless grinders running at peak performance.

Our comprehensive parts inventory means we can respond quickly when you need components. Our experienced technicians bring decades of specialized knowledge to every service call.

We measure our success by your success. When your machines run reliably, hit quality targets, and deliver the productivity you need, we’ve done our job.

Ready to take control of your grinding machine maintenance? Request a quote from Centerless Grinding Solutions today. Let’s work together to build a maintenance program that protects your investment, supports your production goals, and gives you confidence in your equipment reliability.