7 Advantages of Centerless Grinding That Improve Your Production

Precision matters in manufacturing. A part too large or too small means rejected products, wasted materials, and lost time.

Traditional grinding methods introduce uncertainty. Centerless grinding eliminates guesswork, delivering consistent accuracy and faster production speeds.

When you’re manufacturing medical devices, aerospace components, or automotive parts, quality standards are strict. Centerless grinding helps you meet those standards while improving your operational efficiency.

Here are seven advantages of centerless grinding for your production operation.

1. Better Accuracy You Can Count On

Centerless grinding delivers predictable, repeatable precision.

Traditional grinding removes more material than you expect. Move the wheel a small amount, and twice that amount comes off your part. This creates guesswork in getting parts to the right size.

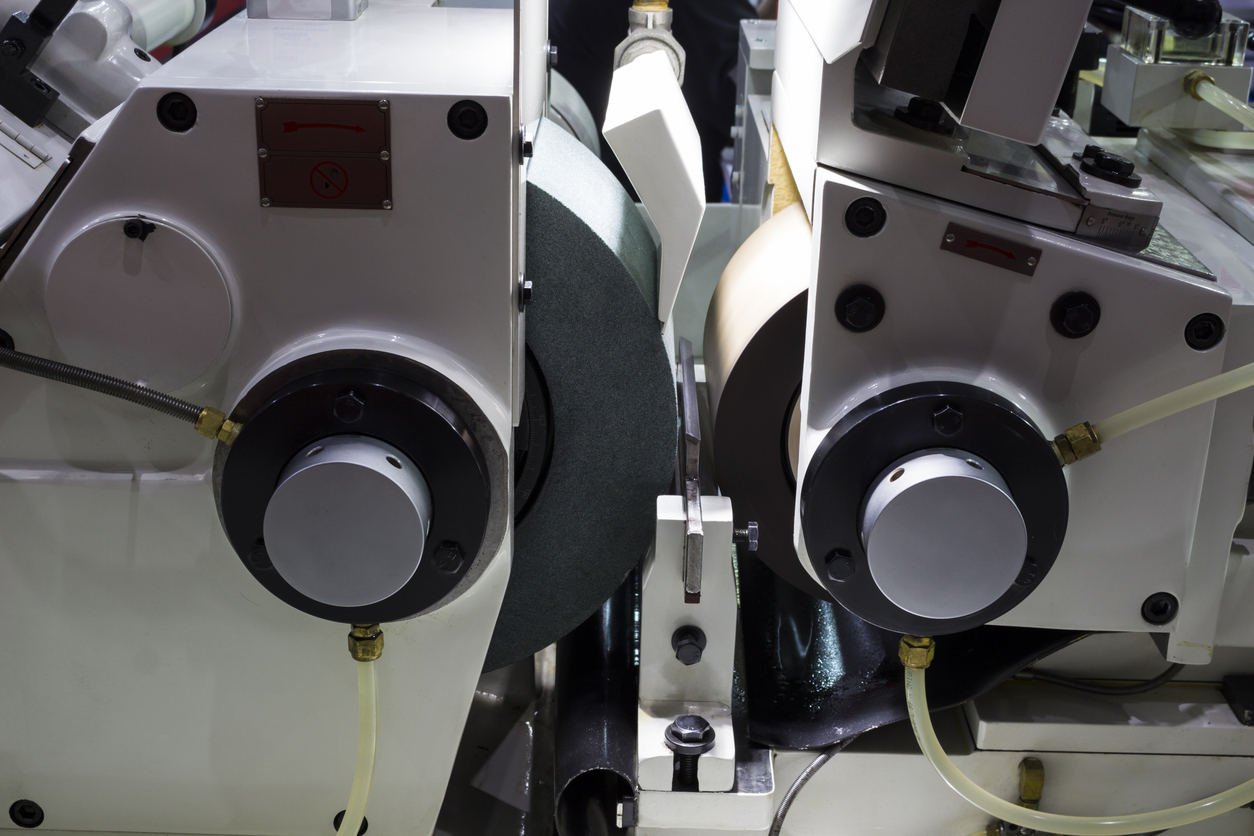

Centerless grinding eliminates guesswork. Your part rotates continuously between two wheels while resting on a support blade. The amount you move the grinding wheel equals the exact amount removed from your part.

This precision matters when size directly impacts how well a part works. Medical device manufacturers need this level of control. Aerospace suppliers depend on it.

The advantage: Predictable results mean better size control, fewer rejected parts, and consistent quality across every production run.

2. Extremely Tight Tolerances

Modern centerless grinding holds parts to incredibly small measurements. We’re talking about differences smaller than the width of a human hair.

This level of precision meets the strict requirements of aerospace and medical device manufacturing. When you’re producing components for aircraft engines or surgical instruments, quality isn’t optional.

Tighter precision means fewer rejected parts. Better surface smoothness means components perform exactly as designed. When you’re running high-volume production, those improvements add up quickly.

The continuous support and consistent grinding action create smooth, uniform finishes without the marks or imperfections affecting other methods.

The advantage: This level of precision reduces waste and improves quality for applications where exact measurements matter most.

3. Superior Surface Finish Quality

Surface quality matters. Rough surfaces create friction, wear parts faster, and compromise performance. For critical applications, surface imperfections mean rejected parts.

Centerless grinding delivers consistently smooth surfaces. Your part rotates continuously between two wheels while resting on a support blade. This continuous contact creates uniform finishes without the tool marks or irregularities common in traditional grinding.

The consistent grinding action produces parts with superior surface finishes that meet stringent inspection standards. You skip secondary finishing operations, saving time and reducing the risk of introducing new defects.

The advantage: Superior surface quality eliminates secondary finishing operations while meeting strict industry standards for critical applications.

4. Versatile Processing Across Materials and Geometries

Your production requirements change. Part sizes vary. Materials differ across product lines.

Centerless grinding handles variation better than you’d think.

The same machine processes different diameters and lengths with simple adjustments. You’re not locked into a single part geometry or material type. Whether you’re grinding hardened steel camshafts or brittle ceramic components, the process adapts.

This flexibility comes from the fundamental design. The grinding wheel, regulating wheel, and workrest blade adjust to accommodate different part sizes without extensive retooling. Feed rates and wheel speeds modify to match material properties.

One well-configured centerless grinder covers a wider range of your production requirements. This reduces capital investment in multiple specialized machines.

The advantage: Equipment versatility means you handle diverse production needs across material types and part geometries with a single machine setup.

5. Minimal Part Damage Through Continuous Support

Traditional grinding methods clamp or center your workpiece, creating stress points causing distortion or damage, especially with thin-walled or delicate components.

Centerless grinding supports the entire length of your part. The workpiece rests on the workrest blade while the grinding and regulating wheels apply balanced forces. No clamping pressure. No stress concentration points.

This gentle support makes centerless grinding valuable for components that’d deform under traditional fixturing methods. You grind longer brittle material without the breakage risk from end pressure or axial thrust.

Medical device manufacturers processing thin-walled tubing benefit from this approach. Automotive suppliers grinding delicate sensor components avoid the reject rates associated with clamping damage.

The advantage: Continuous support without clamping pressure protects delicate components from distortion, reducing breakage rates for thin-walled or brittle parts.

6. Lower Per-Part Costs Through Multiple Efficiencies

Lower per-part costs come from multiple sources in centerless grinding.

Faster cycle times mean more parts per shift. Reduced scrap rates mean less wasted material. Minimal fixturing requirements mean lower tooling costs. The ability to run extended periods without intervention means better labor utilization.

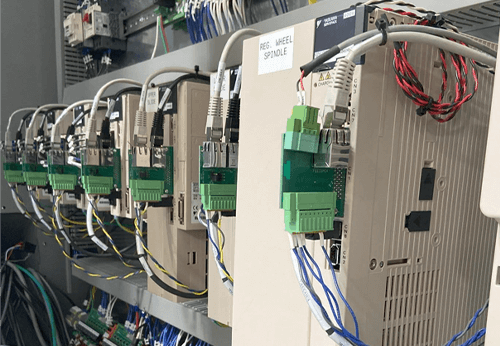

The process requires less maintenance than expected. Wide grinding wheels wear slowly and maintain accuracy for extended periods, especially when using in-process gauging. Fewer adjustments mean less downtime and more consistent output.

These efficiencies compound. A production run producing 1,000 parts per day sees cost savings multiply across faster throughput, lower reject rates, reduced tooling expenses, and minimal supervision requirements.

The advantage: Combined efficiency gains (faster cycles, lower scrap, reduced tooling costs, better labor utilization) create measurable cost advantages improving your competitive position.

7. Stable Setup Requiring Minimal Adjustments

Once you configure a centerless grinder properly, the setup holds. The process is mature and stable. Adjustments become rare rather than routine.

This stability matters when you’re maintaining consistent quality across production runs. You spend less time tweaking parameters and more time producing parts meeting specifications.

The learning curve exists, but once your team understands the fundamentals, setup becomes straightforward. Because the process runs with minimal intervention, you allocate skilled operators to other value-adding activities.

In-process gauging helps maintain accuracy over extended runs. Wheel dressing cycles follow predictable intervals. Parameter drift is minimal compared to other grinding methods.

The advantage: Stable configurations and minimal adjustment requirements free skilled operators while maintaining consistent quality across extended production runs.

Get the Full Advantage of Centerless Grinding

These seven advantages of centerless grinding deliver measurable improvements in precision, efficiency, and cost-effectiveness. The technique has proven itself across aerospace, medical device manufacturing, automotive production, and industries where quality matters.

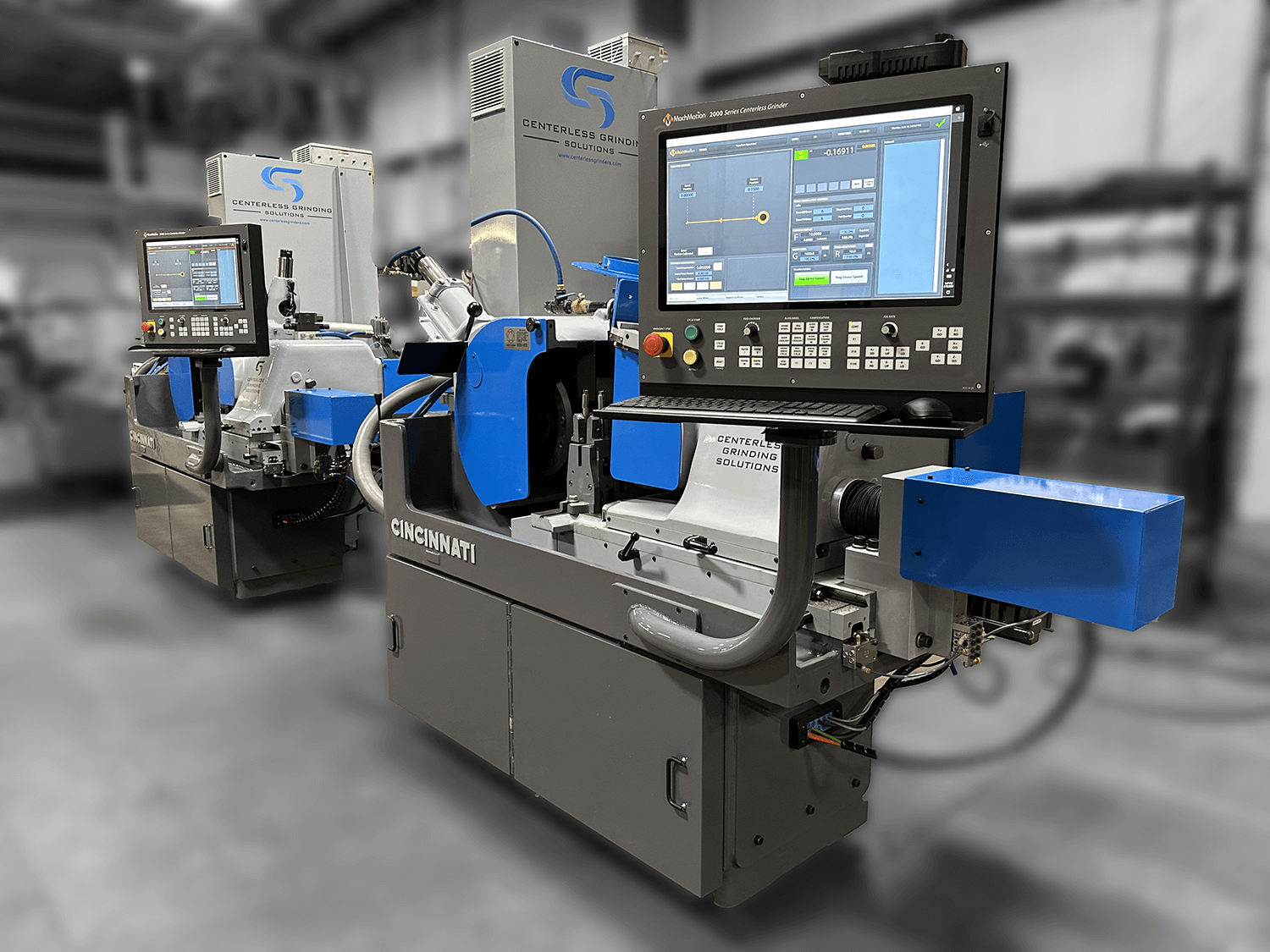

At Centerless Grinding Solutions, we’ve spent over 30 years helping manufacturers optimize their grinding operations. We understand the difference between theoretical capability and real-world performance.

We offer machine remanufacturing services extending equipment life while integrating modern technology. Our parts inventory ensures you maintain peak performance without extended downtime. Our maintenance and upgrade services keep your operations running smoothly.

We’re not supplying equipment. We’re partnering with you to solve production challenges and improve operational efficiency.

If you’re dealing with tight tolerances, high-volume requirements, or challenging materials, let’s talk. Contact us to discuss your specific challenges and explore solutions delivering results you measure.