Equipment purchasing decisions based solely on initial price often result in higher long-term costs and reduced profitability. Total cost of ownership (TCO) for centerless grinding equipment averages 3-5 times the initial purchase price over typical...

How to Fix Common Centerless Grinding Defects

Centerless grinding defects can shut down your job shop operation and cost thousands in scrapped parts. As maintenance managers and plant supervisors know, identifying the root cause quickly makes the difference between minor adjustments and major...

Troubleshooting Component Issues: Signs Your Centerless Grinder Parts Need Attention

Unexpected centerless grinder breakdowns cost manufacturers an average of $50,000 per hour in lost production, yet 80% of component failures show warning signs weeks before catastrophic failure occurs. Recognizing early signs your centerless grinder...

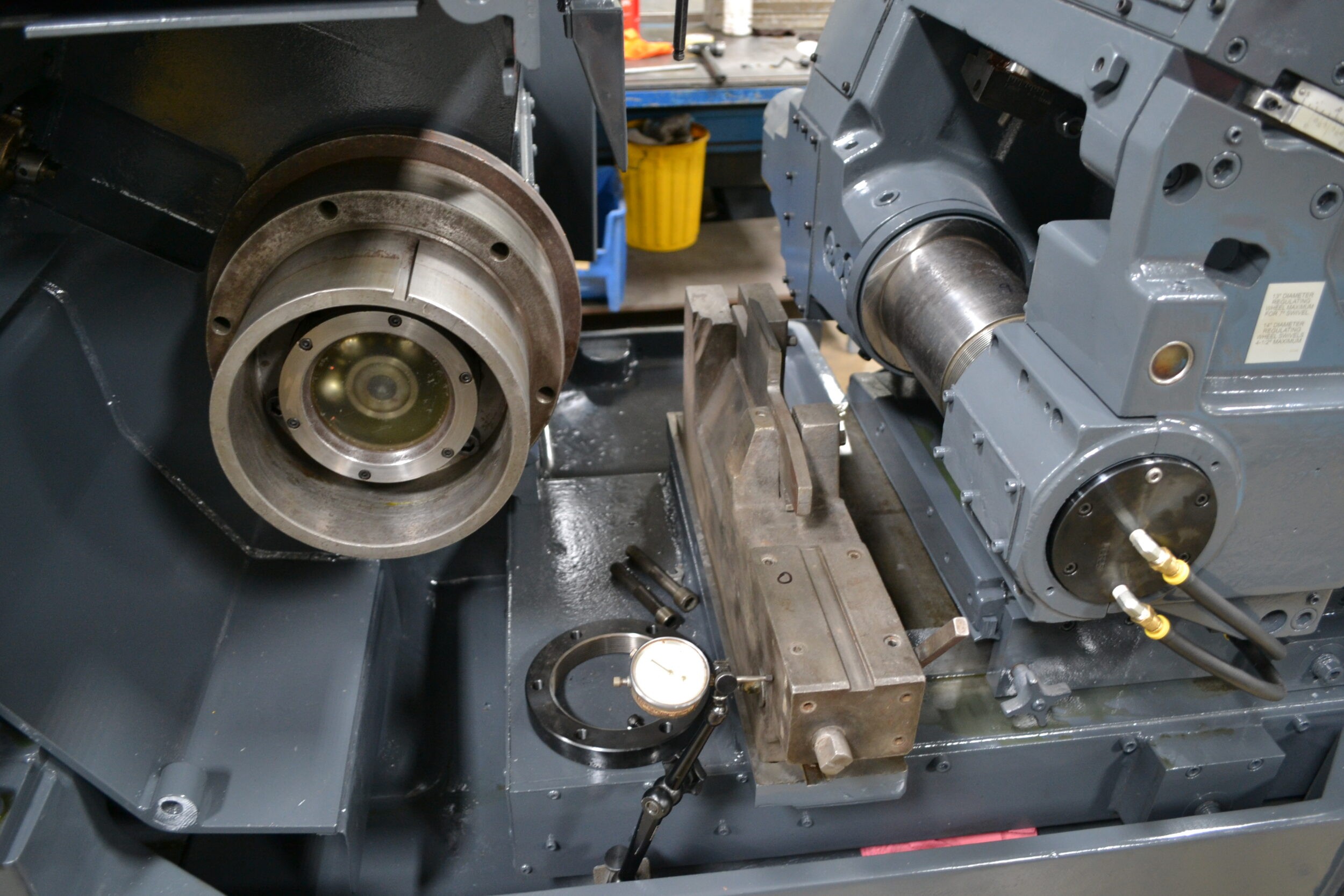

The Impact of Machine Alignment and Setup on Grinding Quality

Poor machine alignment costs manufacturers thousands in scrapped parts and rework. A single misaligned work rest blade can create dimensional errors exceeding 0.0001 inches, turning profitable production runs into costly quality nightmares. Machine...

Comparing Centerless Grinding to Other Grinding Methods

When selecting the optimal grinding method for precision manufacturing applications, understanding the differences between centerless grinding and other grinding techniques is crucial for achieving superior results. Centerless grinding offers unique...

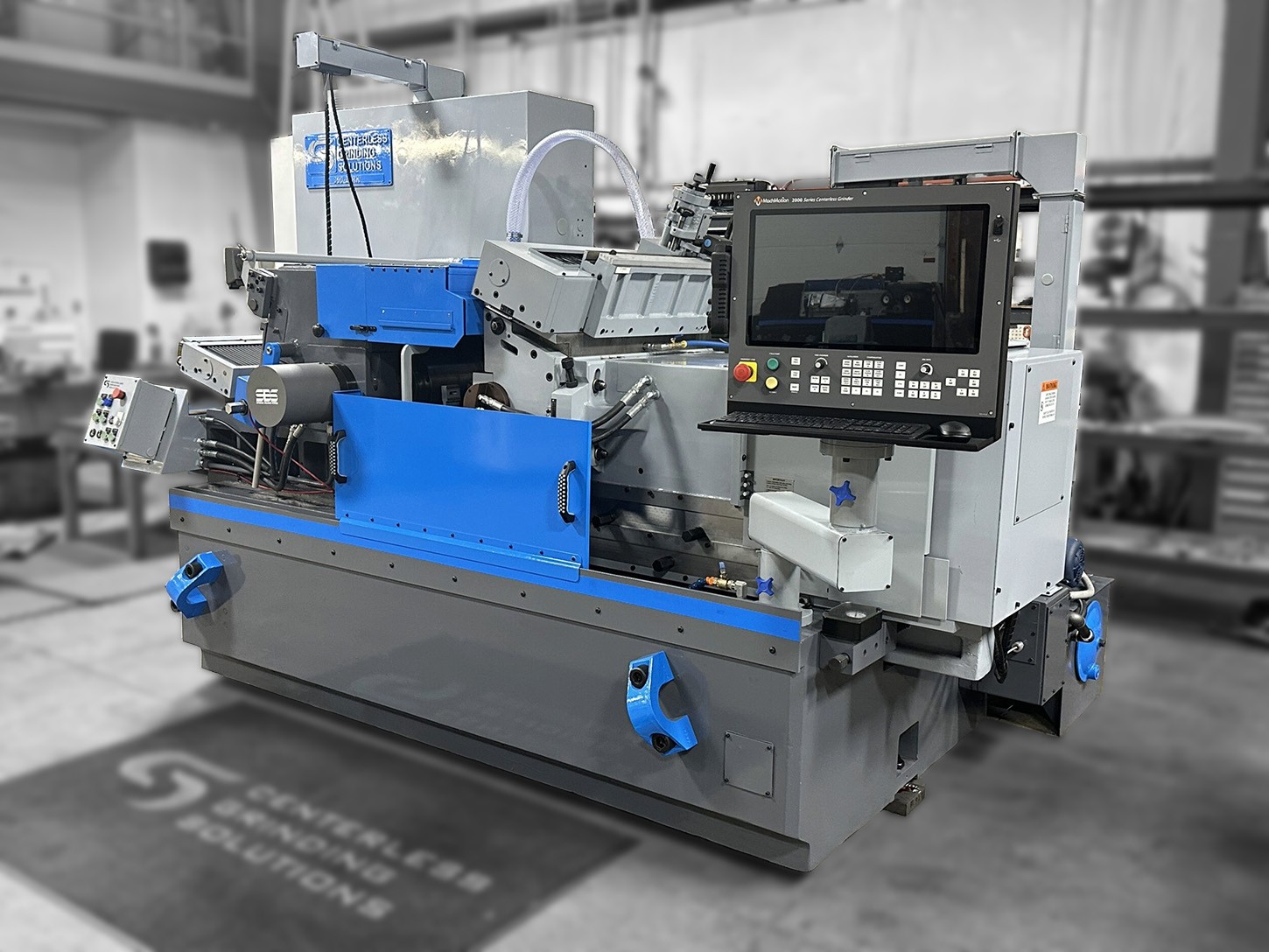

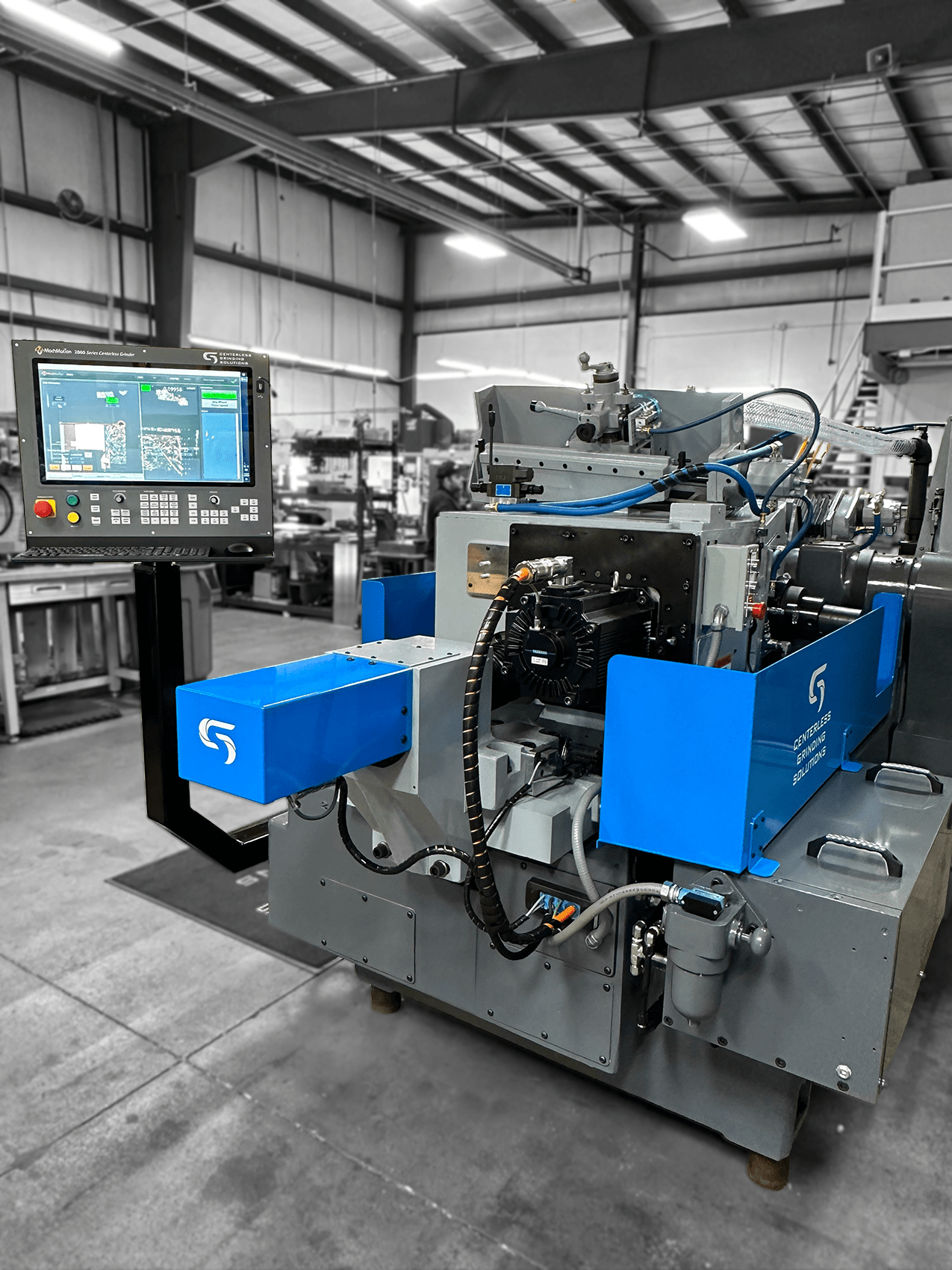

Retrofitting Older Centerless Grinders: What You Need to Know for Maximum ROI

When your centerless grinder shows signs of age but the fundamental machine structure remains sound, retrofitting presents an excellent opportunity to modernize capabilities while avoiding the substantial cost of new equipment. Centerless grinder...

Why Quality Tooling Matters in Centerless Grinding: Tips for Investing in the Best

Manufacturing tolerances keep getting tighter. Yet many shops overlook the very component that makes precision possible - their tooling. A recent client discovered this the hard way when inconsistent part dimensions threatened a major aerospace...

Comparing Centerless Grinder Maintenance Costs: In-House vs. Professional Services

Metal shavings scatter across your workspace as your centerless grinder hums, transforming raw materials into precision-engineered components. But beneath that steady rhythm lies every manufacturer's crucial decision: how to maintain these...

The Secret to Next-Level Grinding with a Grinder Upgrade

Your production line is humming along, but something needs to be fixed. The Cincinnati Milacron centerless grinder, once the pride of your shop floor, is showing its age. Parts aren't meeting the exacting tolerances they once did, and unplanned...

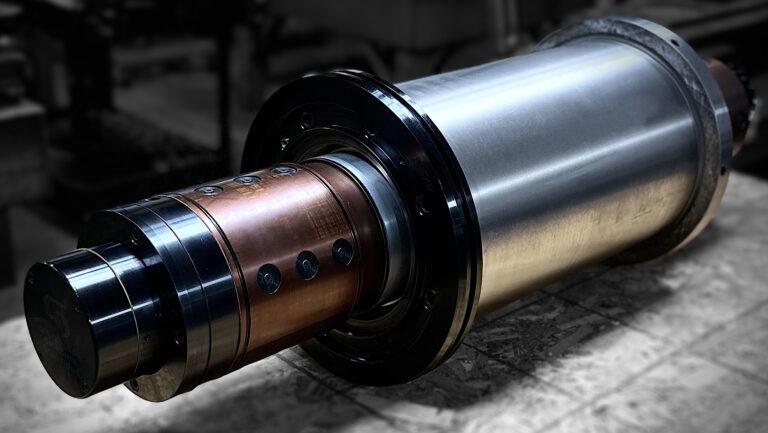

How Does Spindle Health Influence Grinder Productivity?

In the precision machining and centerless grinding industry, productivity is essential. Yet many manufacturers grapple with missed deadlines, increased costs, and subpar product quality without realizing the root cause: an unhealthy...