Your regulating wheel speed isn't just another dial to adjust. It's the control point that determines whether your parts meet spec or end up as scrap. The relationship between your grinding wheel and regulating wheel creates the precision that...

Best Practices for Maintaining Centerless Grinding Machines

Equipment failure is the leading cause of unplanned production stoppages, but it doesn't have to be. A systematic maintenance approach transforms unpredictable breakdowns into manageable, scheduled service windows. This guide walks you through...

Centerless Wheel Balancing: 4 Signs You Need an Automatic System

You know something's wrong when your centerless grinder starts producing inconsistent parts. The surface finish looks rough. Dimensional accuracy drifts. Your maintenance team spends more time troubleshooting than they should. The root cause?...

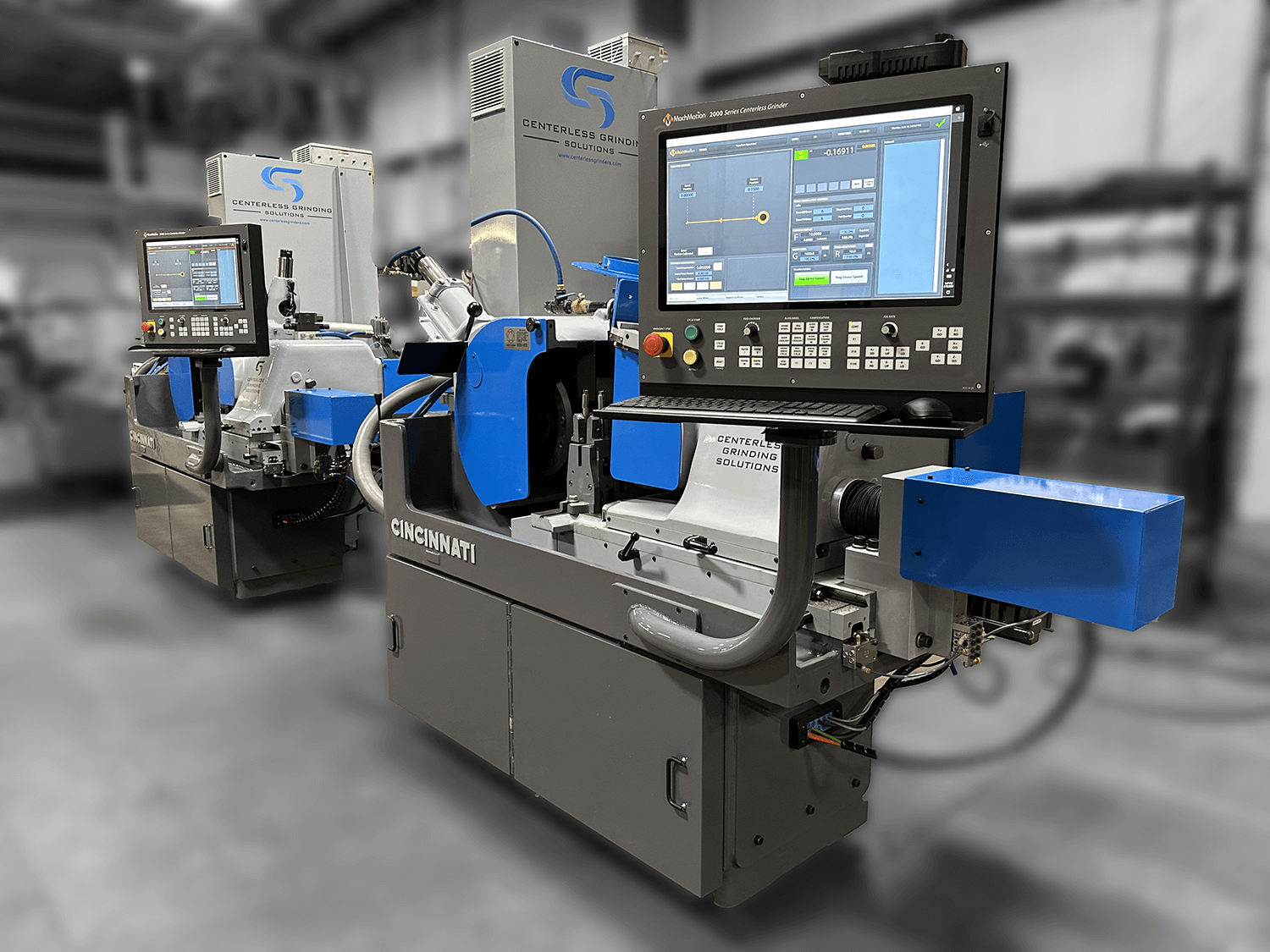

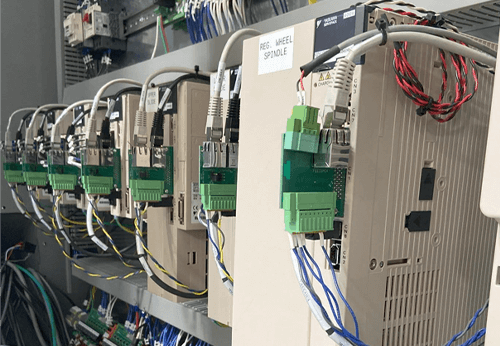

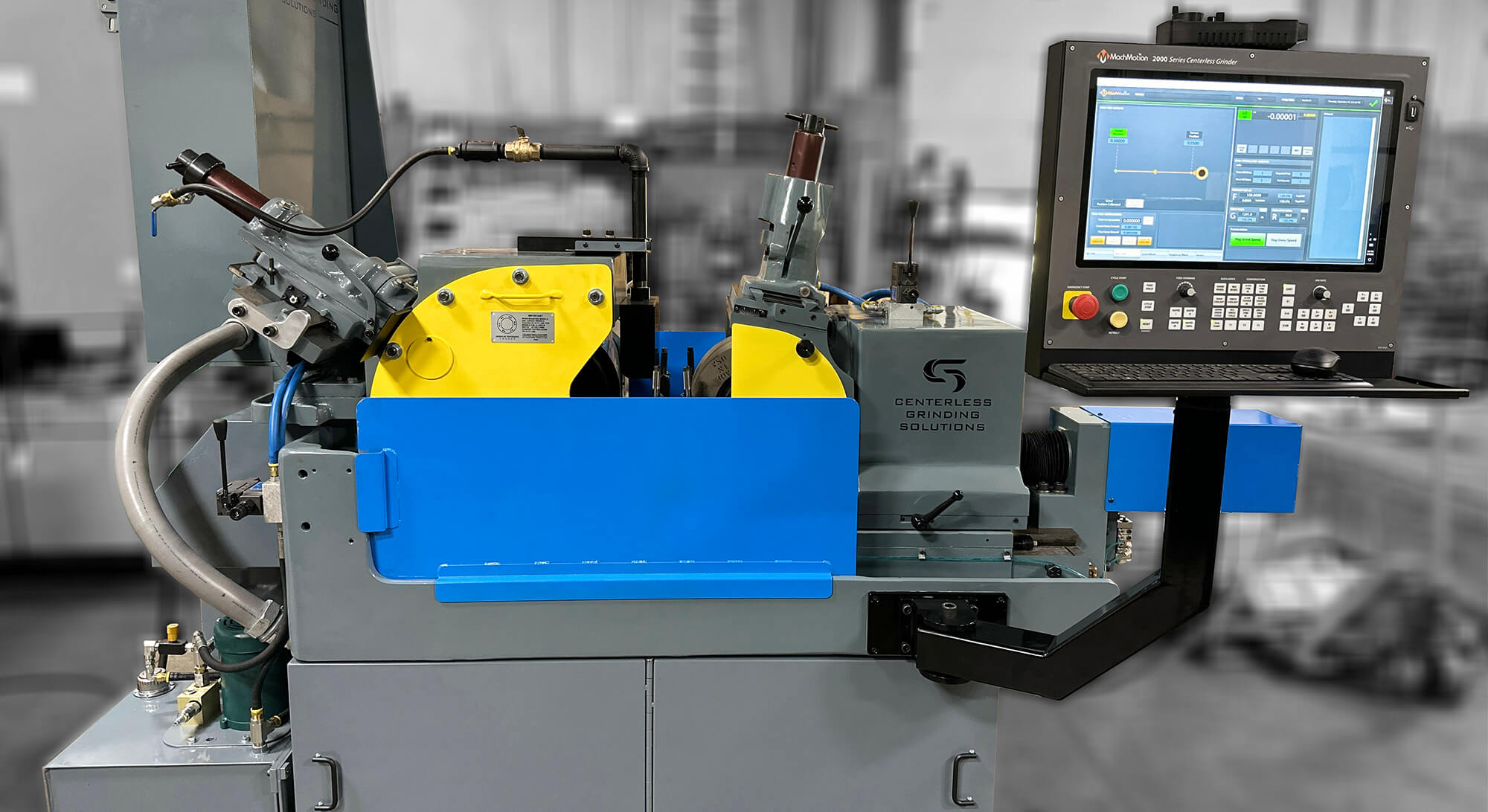

CNC Control Retrofit: Modernizing Centerless Grinding Operations

Centerless grinding has long been a cornerstone of precision manufacturing, shaping everything from automotive components to medical devices with unparalleled accuracy. However, as industries evolve and demand for higher precision and efficiency...

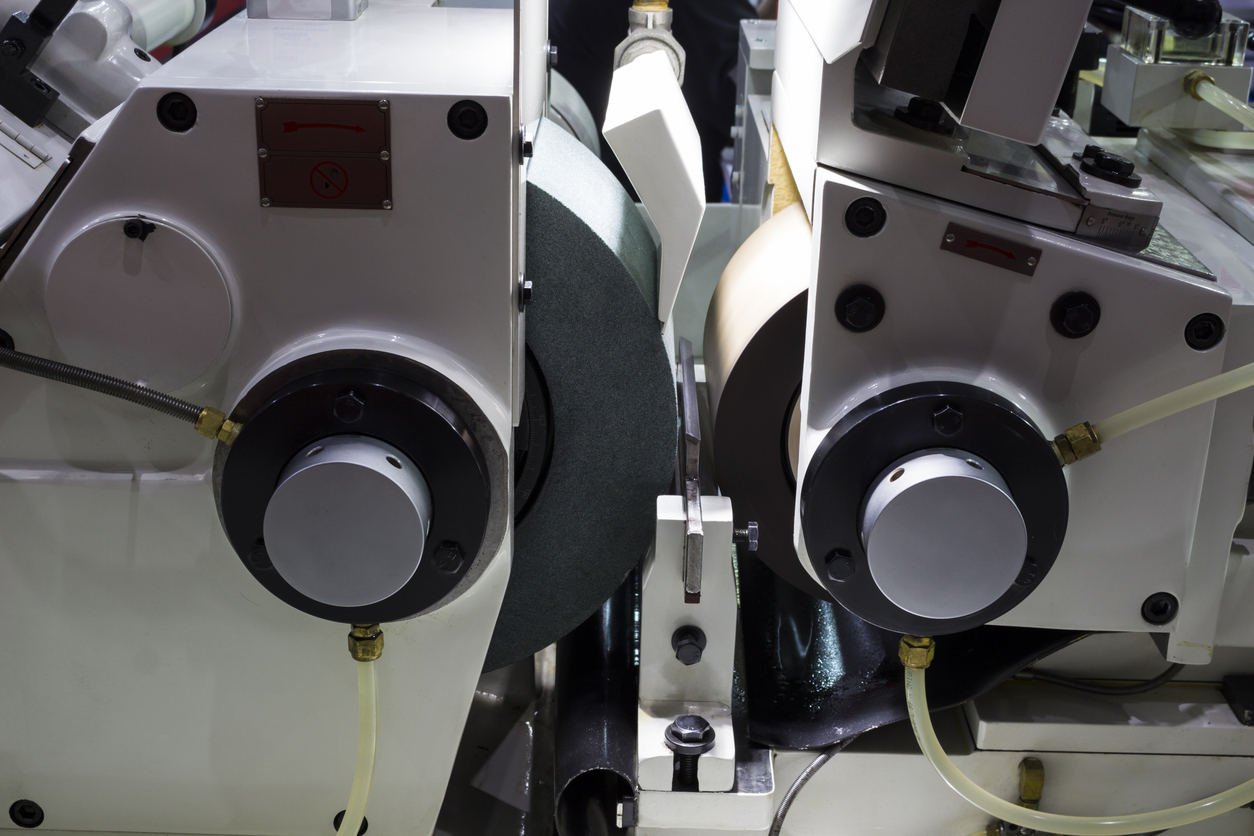

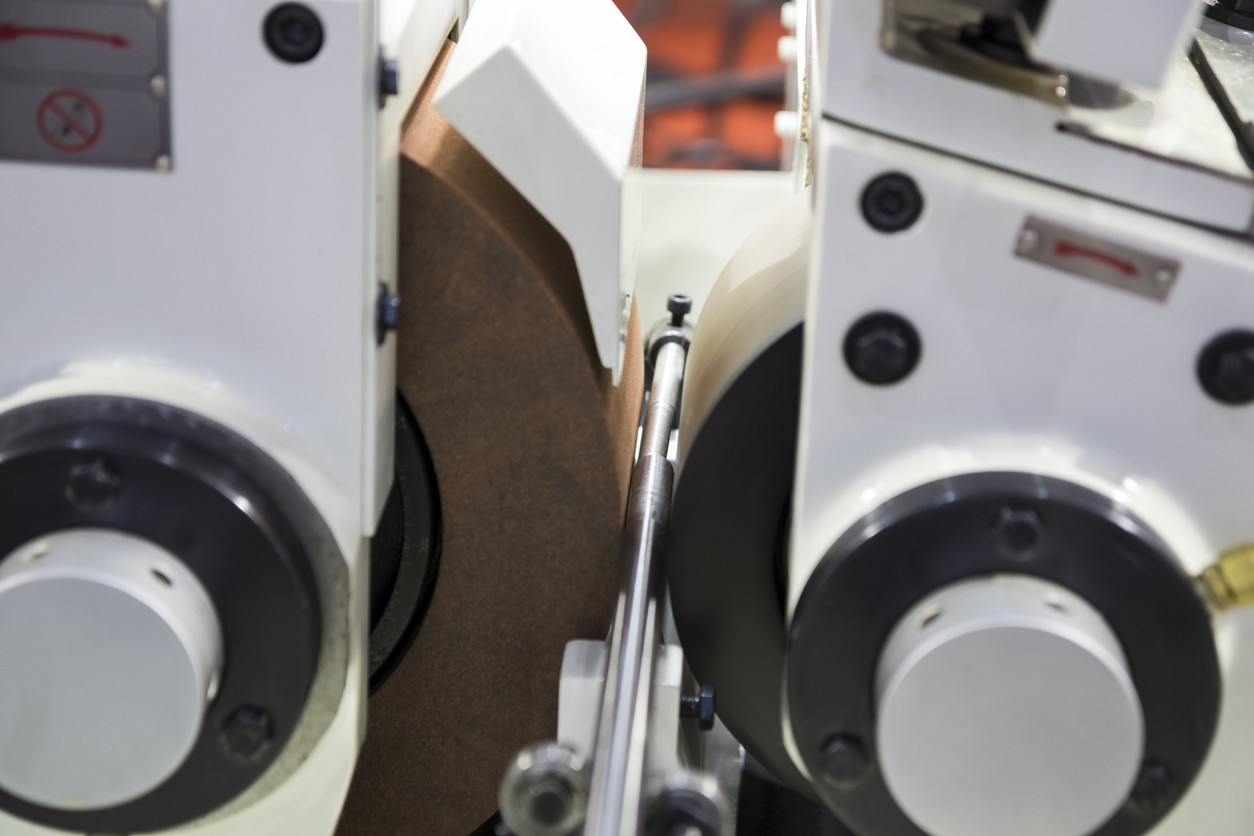

The Complete Guide to the Centerless Grinding Process

For maintenance managers, plant operators, and manufacturing decision-makers, understanding the centerless grinding process is essential. This method delivers precision that other approaches can't match, maintains tight tolerances, and provides...

7 Advantages of Centerless Grinding That Improve Your Production

Precision matters in manufacturing. A part too large or too small means rejected products, wasted materials, and lost time. Traditional grinding methods introduce uncertainty. Centerless grinding eliminates guesswork, delivering consistent...

Preventative Maintenance and Cincinnati Milacron Troubleshooting

Your Cincinnati Milacron grinder runs smoothly until it doesn't. Then everything stops. Unplanned downtime costs major manufacturers $1.4 trillion annually. In automotive manufacturing alone, a single hour of unexpected downtime can drain $2.3...

Centerless Grinder Automation: Unleashing New Efficiencies in Manufacturing

Centerless grinder automation has moved beyond loading robots and basic mechanization. Today's centerless grinder automation systems integrate CNC controls, robotic handling, and real-time process monitoring to deliver precision that manual...

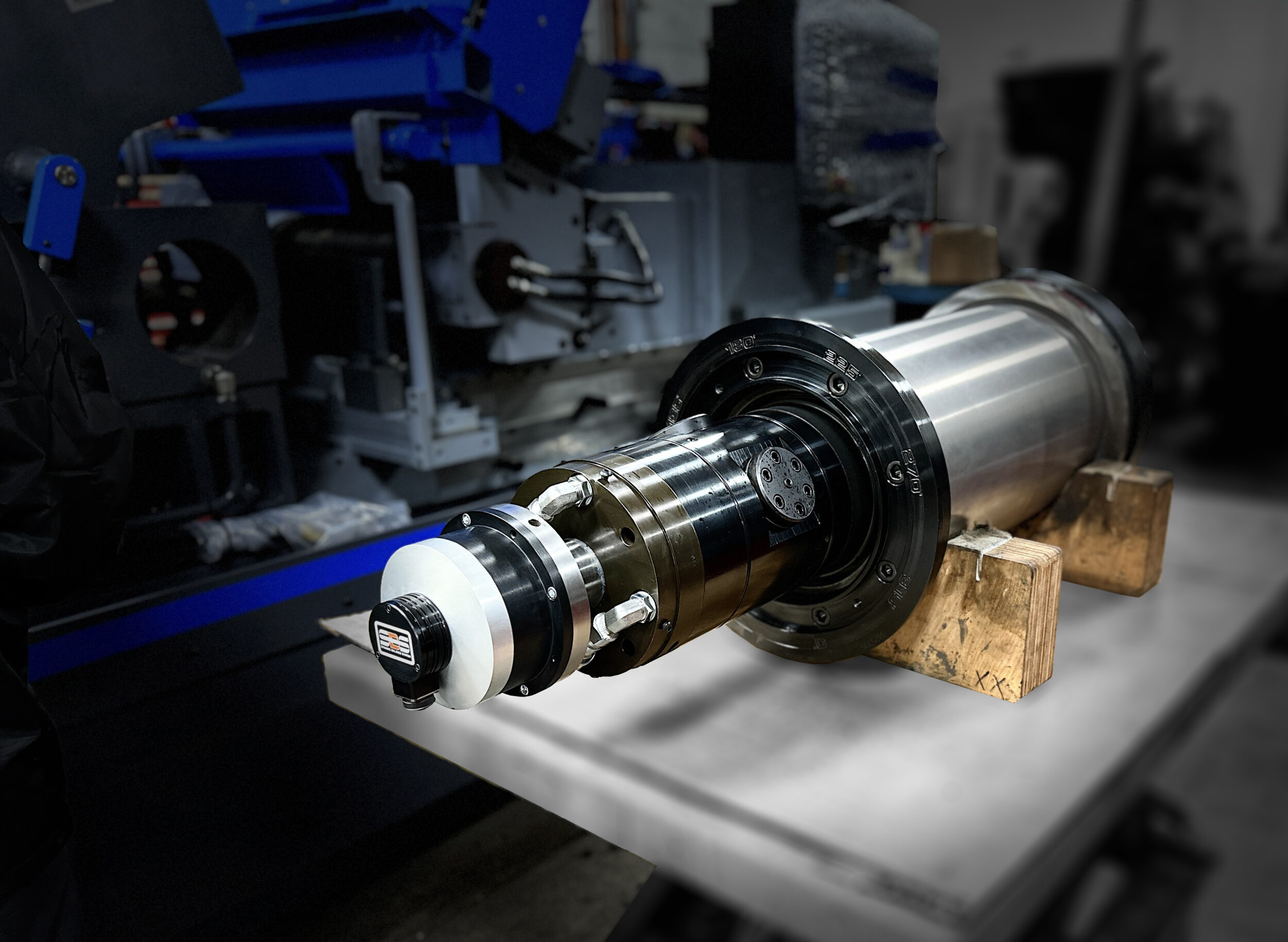

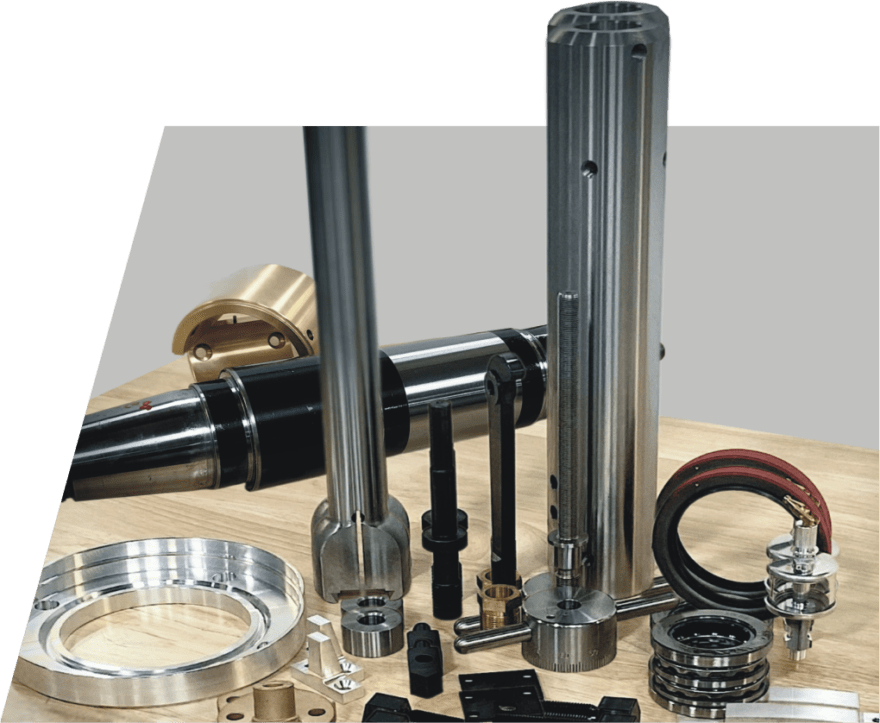

Cincinnati Milacron Replacement Parts: Your Complete Guide to Equipment Longevity

When your Cincinnati Milacron centerless grinder experiences downtime, every minute counts. For manufacturers relying on these precision machines, having access to reliable Cincinnati Milacron replacement parts isn't just convenient—it's essential...

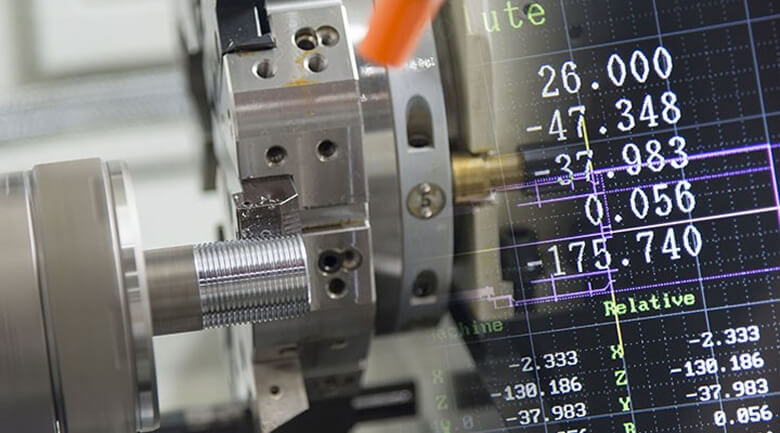

CNC Centerless Grinding: The Complete Guide to Precision and Efficiency

CNC centerless grinding represents a revolutionary approach to precision manufacturing, delivering unmatched accuracy and production efficiency for cylindrical components. This advanced machining process combines computer numerical control with...